Why Choose Limestone Fertilizer Production Solutions?

Limestone fertilizer production solutions involve processing limestone rocks into high-quality fertilizers. These solutions are ideal for enhancing soil fertility and providing essential nutrients to plants. Our company offers advanced equipment and technologies to ensure efficient limestone fertilizer production.

Key equipment for limestone fertilizer production includes ore fertilizer crusher machines, jaw rock crushers, and raymond mills. These machines crush and grind limestone rocks into fine powder, which can then be processed into granules using disc granulator and rotary drum fertilizer granulators. At Yushunxin, we provide high-quality machines that ensure efficient and consistent production.

Limestone fertilizer production solutions improve soil structure and increase crop yields. By using advanced crushing and granulating machines, you can produce high-quality fertilizers that enhance soil fertility. Our solutions are designed to optimize production efficiency and minimize waste, ensuring sustainable and profitable operations.

Part 2: How to Optimize NPK Fertilizer Manufacturing?

NPK fertilizer manufacturing involves producing fertilizers that contain nitrogen, phosphorus, and potassium. These essential nutrients promote healthy plant growth and improve crop yields. Our company offers comprehensive solutions for efficient NPK fertilizer production.

Essential equipment for NPK fertilizer manufacturing includes ore fertilizer crusher machines, jaw rock crushers, and screening machines. These machines process raw mineral materials into fine particles, which are then mixed and granulated using rotary drum fertilizer granulators and double roller press granulators. At Yushunxin, we provide high-quality machines that ensure precise mixing and granulation.

Part 3: What Makes Bulk Fertilizer Blending Plant Solutions Effective?

Bulk fertilizer blending plant solutions involve mixing different types of fertilizers to create customized blends. These solutions are ideal for meeting specific crop nutrient requirements. Our company offers advanced equipment and technologies for efficient bulk fertilizer blending.

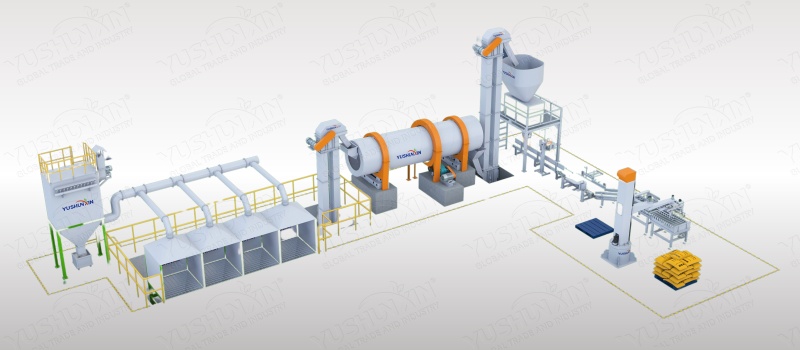

Key equipment for bulk fertilizer blending includes ore fertilizer crusher machines, jaw rock crushers, and screening machines. These machines process raw mineral materials into fine particles, which are then blended using advanced mixing equipment. At Yushunxin, we provide high-quality machines that ensure precise blending and consistent quality.

Bulk fertilizer blending plant solutions allow you to create customized fertilizer blends that meet specific crop nutrient requirements. Our advanced equipment ensures precise mixing and consistent quality, enhancing production efficiency. By investing in our bulk fertilizer blending plant solutions, you can achieve higher crop yields and improved soil fertility, contributing to sustainable and profitable operations.

Part 4: Why Invest in Rock Phosphate Fertilizer Production?

Rock phosphate fertilizer production involves processing phosphate rocks into high-quality fertilizers. These fertilizers provide essential phosphorus to plants, promoting healthy growth and improved crop yields. Our company offers comprehensive solutions for efficient rock phosphate fertilizer production.

Essential equipment for rock phosphate fertilizer production includes ore fertilizer crusher machines, jaw rock crushers, and raymond mills. These machines crush and grind phosphate rocks into fine powder, which can then be processed into granules using disc granulator machines and rotary drum fertilizer granulators. At Yushunxin, we provide high-quality machines that ensure efficient and consistent production.

Rock phosphate fertilizer production solutions enhance soil fertility and increase crop yields. By using advanced crushing and granulating machines, you can produce high-quality fertilizers that provide essential phosphorus to plants. Our solutions are designed to optimize production efficiency and minimize waste, ensuring sustainable and profitable operations.