Rock Phosphate Fertilizer Production

Mining, chemical industry, building materials, fertilizer plants, etc.

1-30 t/h

7.5-22 kw

3-10 mm

Phosphate fertilizer is a fertilizer mainly with phosphorus element. Phosphate fertilizer is an important mineral fertilizer in agriculture, which plays a vital role in promoting food production. As one of the three main fertilizers (the other two are nitrogen and potash fertilizers), phosphate fertilizer is critical to ensuring healthy crop growth and increasing yields. In fact, phosphorus is one of the essential elements for all living things. It participates in the energy conversion process of plants and plays an indispensable role in root development, flower and fruit formation and maturity.

What are the raw materials of phosphate fertilizer?

The main raw material of phosphate fertilizer is phosphate rock, which is a natural ore containing phosphate minerals. There are many types of phosphate minerals in phosphate rocks. But they can mainly be divided into the following categories:

- Apatite: Apatite is one of the most important phosphate rocks, and its chemical composition is mainly fluorapatite and chloroapatite. Apatite is widely distributed around the world and is the main source of phosphate fertilizers for industrial production.

- Phosphate rocks: These rocks contain a variety of different phosphate minerals, including apatite. Also, phosphate rocks are another important source of phosphate fertilizers.

- Clay Phosphate: Clay in some specific areas contains a higher proportion of phosphate, and these clays can also be of use as raw materials for phosphate fertilizers.

In addition to natural phosphate rocks, there are other sources of phosphorus can also be of use in the production of phosphate fertilizers, such as animal bone meal, municipal sludge and livestock and poultry manure. These are also the main raw materials to make phosphate fertilizers.

Top 2 Essential Shunxin Phosphate Ore Crushing Equipment in 2024

How much does it cost to establish a phosphate fertilizer production line?

The cost of a phosphate production line for producing phosphate fertilizer depends on many factors, including the size of the production line, production capacity, technology, type of raw materials, etc. Therefore, it is very difficult to give an accurate cost, and there is no unified standard. However, we can provide some rough guideline numbers to help you develop a preliminary idea of your budget.

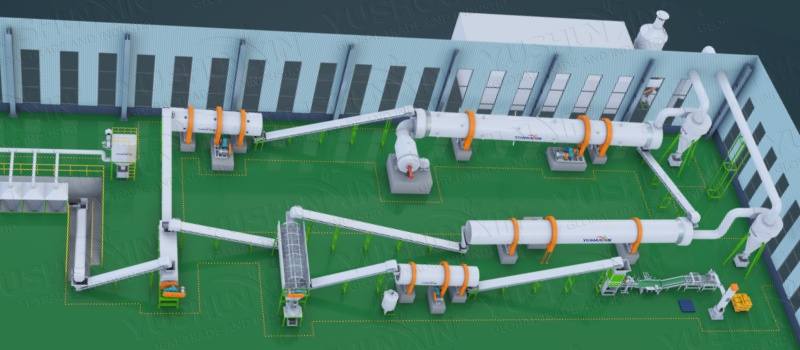

What is the process of phosphate fertilizer production?

The production process of phosphate fertilizer involves multiple steps, including beneficiation, acidification, precipitation, filtration, concentration, drying and packaging of raw materials. The following are the detailed steps of the phosphate fertilizer production process:

In addition, according to production needs, phosphate fertilizer production can also be divided into the production of single phosphate fertilizer and compound phosphate fertilizer. Specifically, the production of compound phosphate fertilizer is to mix phosphate, nitrogen fertilizer and potassium fertilizer together and control them in a specific proportion to produce a compound fertilizer containing three elements.

What are the main factors affecting the quality of phosphate fertilizer production?

As a company specializing in fertilizer equipment, Shunxin has received unanimous trust from manufacturers at home and abroad. We can provide you with various quality and sophisticated fertilizer equipment. Whether you use it for small-scale production or large-scale production, we can recommend you with production equipment lines suitable for all production capacities. Therefore, if you want to build your phosphate fertilizer production line, please feel free to contact us to inquire about detailed equipment plans and quotations.