Raymond Mill

Mining, chemical industry, building materials, etc.

3.5-45 T/H

55-180 kw

18-92 T

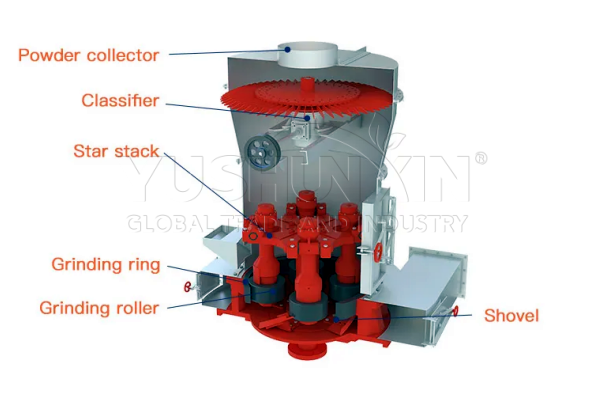

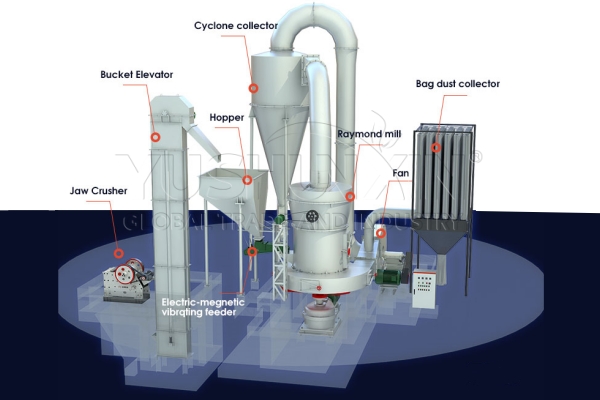

Raymond Mill is a type of grinding mill or pulverizer that could grind mine material into fine powder. It is one of the most widely used grinding machines all over the world. Moreover, Raymond mill is suitable for the high fine processing of mineral rocks. On the whole, it can process hundreds of mineral materials with molar hardness not greater than 7 and humidity below 6%. By using this crusher, the particle size range of the finished product is between 40-400 mesh. This kind of machine is capable of processing hard mine rocks into powders. Exactly, the finished powder often plays an important role in agricultural production as a high-quality mineral fertilizer.

What Mineral Material Is That Suit For Raymond Mill?

Raymond Mills Have A Broad Range Of Applications And Can Grind Various Mineral Materials Such As:

Limestone, barite, bentonite, kaolin, gypsum, cement, dolomite, marble, calcite, phosphate rock, fluorspar, potash feldspar, talc, lime, quartz, activated clay, activated carbon, etc.

Furthermore, after grinding into fine powders by Raymond Mill, these mineral materials are finally put into use in various industries, especially in processing compound fertilizer fields.

When Use Raymond Milling System?

What kind of feedback do customers give to our Raymond mill?

A Customer From Kenya Told Us His Experience Of Using Shunxin Raymond Mill:

Three months ago, we bought a Raymond mill for organic fertilizer production line. Since it was put into use, the effect is very remarkable.

First of all, the Raymond mill has a very high crushing efficiency, which greatly improves our production efficiency. Not only that, we are also satisfied with the uniform fineness of its discharge, which plays a key role in improving the quality of the final product. In addition, it also has good performance in terms of its energy consumption. It reduces the pressure of production cost to a certain extent, which is very important for enterprises like us that focus on sustainable development.

All in all, we are very grateful to SX Fertilizer Equipment Company for providing us with professional support and excellent service. Also, we look forward to more cooperation opportunities in the future.

Parameters of Raymond Mill

| Model | Roll Ring Dia. (mm) | Capacity (t/h) | Max Feed Size (mm) | Finished Size (mm) | Weight (t) | Motor Power (kw) | Dimension (L*W*H) |

| SXLM-500 | 500 | 0.5-2 | 15 | 1.6-0.045 | 1.8 | 7.5 | 3000*2000*3600 |

| SXLM-650 | 650 | 0.5-2.5 | 15 | 2.8 | 15 | 3500*2500*3800 | |

| SXLM-780 | 780 | 1.0-3.0 | 15 | 3.8 | 18.5 | 4300*3500*4800 | |

| SXLM-980 | 980 | 1.5-4 | 20 | 6.5 | 30 | 5300*4000*5000 | |

| SXLM-1100 | 1100 | 2.0-6.0 | 25 | 14.5 | 45 | 7000*5900*7000 | |

| SXLM-1450 | 1450 | 6.0-10.0 | 30 | 26 | 90 | 9000*6000*8000 | |

| SXLM-1760 | 1760 | 11.0-20.0 | 30 | 48 | 132 | 11050*10010*10010 | |

| SXLM-1950 | 1950 | 15-30 | 40 | 65 | 185 | 12850*10080*9980 | |

| SXLM-2100 | 2100 | 30-45 | 50 | 1.6-0.075 | 85 | 220 | 14730*10860*10341 |

In conclusion, Raymond Mill is an indispensable tool in various industries due to its versatility, efficiency, and reliability in grinding a wide range of mineral materials into fine powder. Because of its energy-efficient operation and ease of maintenance, therefore making it a popular choice for many manufacturers. In a word, Raymond Mill plays a crucial role in the mineral waste disposal industry by grinding minerals and ores such as phosphate ore, potash ore, and so on into usable products. Furthermore, you can use finished materials like limestone, and gypsum powder to make further processing in fertilizer production lines.