Mineral Organic Fertilizer Production Line

Mining, chemical industry, building materials, fertilizer plants, etc.

1-30 t/h

7.5-22 kw

3-10 mm

Mineral organic fertilizer is a compound fertilizer that effectively combines organic matter and minerals. Specifically, it is rich in organic material. Also, it contains a variety of mineral components. For instance, nitrogen, phosphorus, potassium, as well as trace elements such as iron, zinc, copper and so on. For this purpose, this fertilizer not only provides the nutrients needed for plant growth, but also improves the soil. Thereby, it promotes healthy crop growth and improving soil fertility.

What Are The Raw Materials of Mineral Organic Fertilizer?

The main raw materials of mineral organic fertilizer include natural minerals and organic matter. Among them, minerals can be various natural ores or processed mineral powders, while organic matter mainly comes from composted materials such as animal manure and plant residues, or artificially synthesized organic matter.

Raw Materials for Fertilizer Production Line

In addition, in order to adjust the properties of fertilizer and improve its effect, some auxiliary raw materials are sometimes added, such as microbial inoculants, humic acid, amino acids, etc. These auxiliary raw materials can enhance the biological activity of fertilizers, improve fertilizer efficiency, and promote crop growth and development.

What is the production line of mineral organic fertilizer?

The mineral organic fertilizer production line refers to a complete set of production equipment and processes specifically used to produce mineral organic fertilizers. This production line combines organic materials and mineral elements to produce compound fertilizers that are both rich in organic matter and supplemented with necessary mineral elements. Thus, it can fully provide minerals for plant growth, while improve the soil structure and soil fertility. Furthermore, this production line covers all production processes from raw material processing to finished product packaging. Through a series of automated and mechanized equipment, it achieves efficient and large-scale production of mineral organic fertilizers.

What is the total cost of setting up a mineral organic fertilizer line?

The cost of setting up a mineral organic fertilizer production line is affected by many factors. For example, the scale of the production line, output, geographical location, raw material and energy costs, as well as the quality and technical level of the selected equipment.

-

For small mineral organic fertilizer production line

The cost of a small mineral organic fertilizer production line is between US$50,000 and US$300,000. Such production lines usually include basic processing equipment such as crushers, mixers, granulators, dryers, and packaging machines.

-

For medium to large mineral organic fertilizer production line

If you plan to build medium to large mineral organic fertilizer production lines. That is, a production line with an annual processing capacity of tens of thousands of tons or more. And the production line construction cost may range from 300,000 to several million US dollars.

In addition, other relevant factors that you should take into consideration. Such as site construction, warehousing, logistics, staff training and operating capital. At the same time, in order to ensure that the production line complies with local environmental protection and safety standards, you need to spend additional investment to purchase environmental protection equipment and safety equipment.

What Are The Composition of Mineral Organic Fertilizer Production Line?

- Raw material pretreatment system

- In the mineral organic fertilizer production line, raw material processing is the first step, including the collection, screening, crushing and mixing of various minerals and organic matter. After preliminary processing, these raw materials are precisely measured and mixed according to a specific formula to ensure the balance and effectiveness of each element in the fertilizer.

- Mineral organic fertilizer crusher for sale

- Shunxin mineral organic fertilizer crusher can to crush raw materials to meet the particle size requirements for subsequent processing. Through the crushing process, you will obtain mineral organic fertilizer particles with uniform particle size. And it is beneficial to improving the efficiency and quality of subsequent granulation. Therefore, choosing the right crusher is essential. Our company provides many types of crushing equipment, such as new vertical crushers and semi-wet material crushers.

- Mineral organic fertilizer mixer for sale

- Mineral organic fertilizer mixer is an important equipment to mix raw materials in the production process of organic fertilizer. It not only mixes mineral and organic materials, but also adds other necessary nutrients to prepare a uniform fertilizer mix. Therefore, we have a wide range of mixers for you to choose from that can perfectly meet your production needs.

Granulation system

Next, the mixed materials will enter the granulator for pelletizing. During the granulation process, by controlling parameters such as temperature, humidity, and particle size, granular fertilizer will finally meets the requirements.

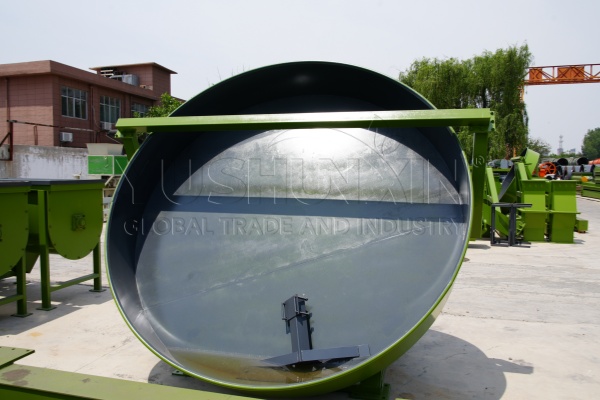

- Rotary Drum Granulation Machine For Sale

- The drum granulator is one of the commonly used granulation equipment, through the rolling of the material polymerization into spherical particles. The drum granulator is suitable for large-scale granulation production lines, and its output can reach 1-30t/h. It has the advantages of high productivity and low energy consumption. Besides, the equipment adopts the agglomeration wet granulation method to make the mineral organic fertilizer particles more uniform and round.

- Pan Granulator for Mineral organic fertilizer

- The pan granulator is suitable for small and medium-sized mineral organic fertilizer granulation production, it adopts wet granulation method. Mineral organic fertilizers gradually aggregate into spherical particles in the tilted rotating disk under the action of water or binder. It not only has a simple structure and flexible operation, but also has a granulation rate of over 93%. Therefore, due to its high efficiency, it becomes one of the first choice for many mineral fertilizer manufacturers.

What are the feedback from customers who purchased our fertilizer equipment?

In today’s agricultural production, efficient and environmentally friendly fertilizer equipment has become a key factor in improving crop yield and quality. As a company specializing in the production of fertilizer equipment, Shunxin has received a lot of praise at home and abroad. We have received feedback from many customers who have spoken highly of the quality and price of our fertilizer equipment.

For example, a customer from Bolivia shared his experience after using our mineral organic fertilizer production line. He said that the production line is not only easy to operate, but also consumes low energy. The fertilizer produced is of excellent quality, which greatly improves the yield and quality of crops. Thus, it makes his agricultural products more competitive in the market.

Nowadays, customers unanimously believe that our fertilizer equipment is extremely cost-effective in the market. This is due to our efforts to continuously optimize production processes and streamline management costs. So that even cheap products can guarantee advanced technology and reliable quality. What is more, our equipment can not only improve the efficiency of fertilizer production, but also ensure the stable quality of the fertilizer produced. Thus, it helps them gain an advantage in the fierce market competition.