Manufacturing of NPK Fertilizer

Mining, chemical industry, building materials, fertilizer plants, etc.

1-30 t/h

7.5-22 kw

3-10 mm

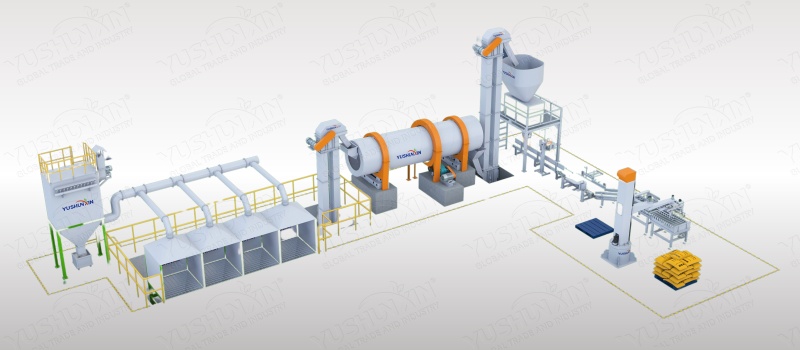

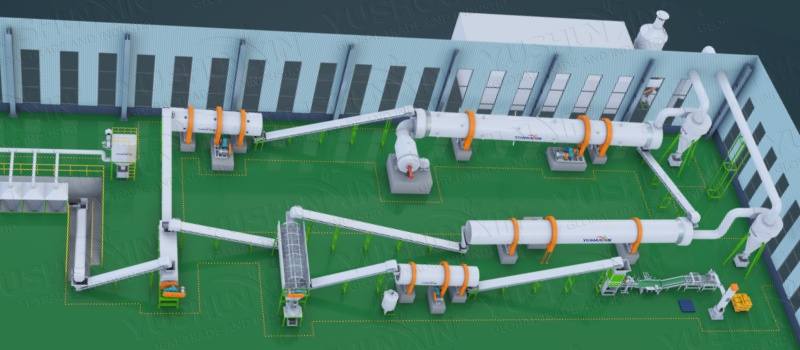

NPK fertilizer is a compound fertilizer whose main ingredients include nitrogen, phosphorus and potassium. These three elements are indispensable nutrients for plant growth. This type of compound fertilizer is widely used in agricultural production as it helps improve crop yield and quality by providing a variety of important nutrients needed for plant growth. Currently, there are two NPK fertilizer processing methods in the NPK fertilizer industry. One is to convert powdered fertilizer raw materials into NPK fertilizer particles, and the other is to mix the prepared single nitrogen, phosphate fertilizer, and potassium fertilizer particles. Concerning to these two NPK fertilizer production methods, Shunxin machinery designed NPK fertilizer equipment for fertilizer manufacturers. If you want to build a complete NPK fertilizer production line, then Shunxin Machinery Company can meet your needs. Here you can find everything you want.

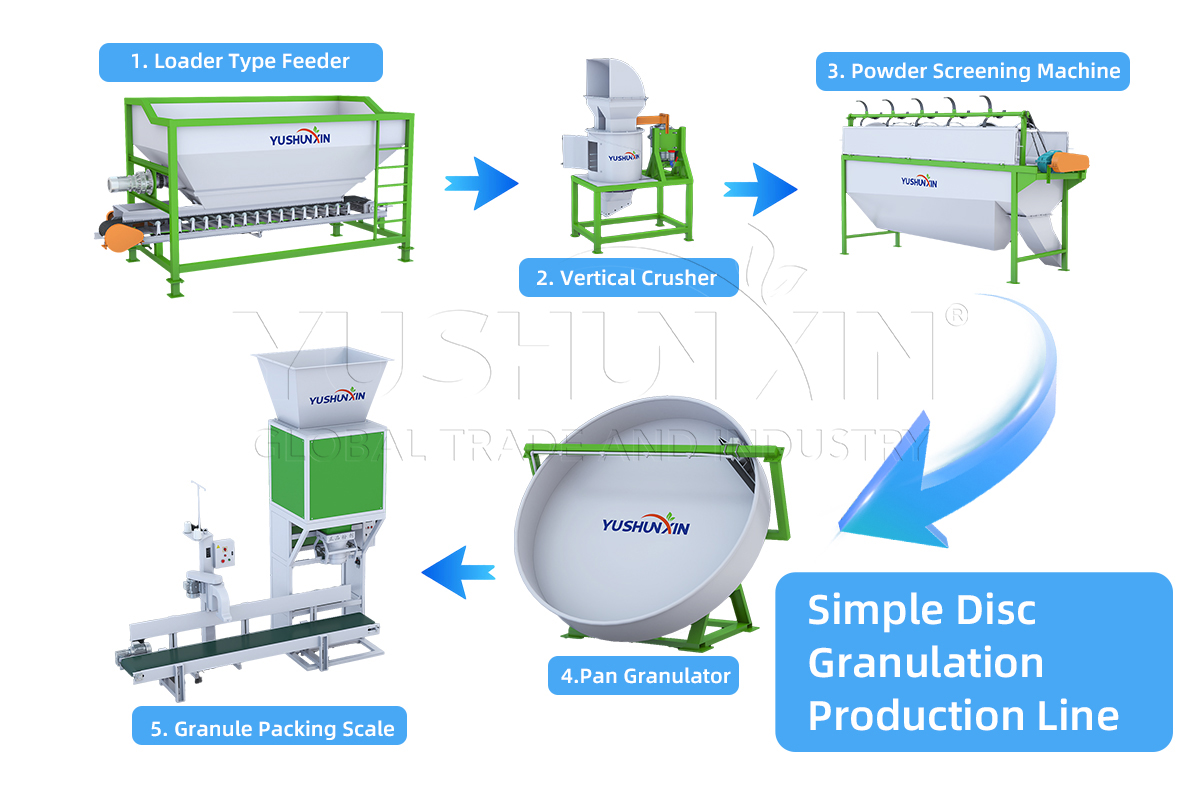

2 Types of NPK fertilizer production line

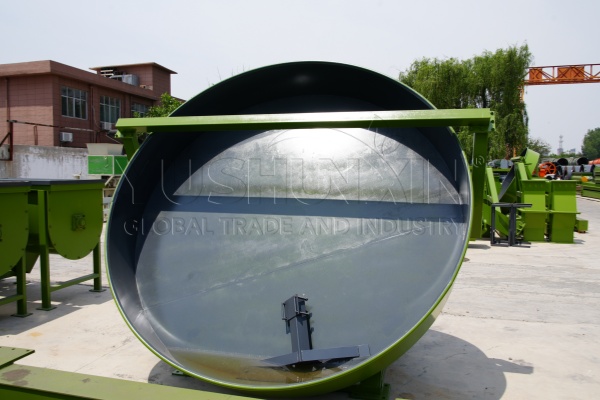

What is the key equipment in the NPK fertilizer production line?

NPK fertilizer granulation equipment is an important component in the NPK fertilizer production line. It is mainly used to convert NPK powder fertilizer into granules for easy use and transportation. Therefore, if you have needs for NPK fertilizer granulation, then we have the following 2 types of Shunxin granulators for you to choose from:

What Are Suitable Raw materials for Manufacturing of NPK Fertilizer?

The raw materials of NPK fertilizers are mainly derived from natural resources and industrial by-products, including the following types:

- Nitrogen fertilizer(N): urea, ammonium sulfate, ammonium nitrate, ammonium chloride, calcium nitrate, etc. Among them, urea is the most commonly used nitrogen fertilizer raw material because of its high nitrogen content and good solubility.

- Phosphorus fertilizer(P): Mainly superphosphate, heavy superphosphate, calcium magnesium phosphate fertilizer, etc. Another important phosphorus source is calcium dihydrogen sulfate, which can be directly used as a fertilizer raw material or can be converted into Phosphates are used

- Potassium fertilizer(K): Potash minerals are the main source of potassium fertilizers, such as potassium chloride and potassium sulfate. In addition, there are some industrial by-products containing potassium that can also be used in fertilizer production, such as fireweed ash.