Limestone Fertilizer Production Solutions

Mining, chemical industry, building materials, fertilizer plants, etc.

1-30 t/h

7.5-22 kw

3-10 mm

The main component of the limestone is calcium carbonate, and limestone fertilizer is a mineral fertilizer that based on limestone powder. It is mainly composed of calcium carbonate and magnesium carbonate, and also contains trace elements such as manganese and boron. Limestone fertilizer specifically refers to the magnesium content, while lime generally refers to calcium. Limestone fertilizer plays a vital role in agriculture. Processed limestone fertilizer can be used to improve soil pH and soil health, thereby increasing agricultural productivity.

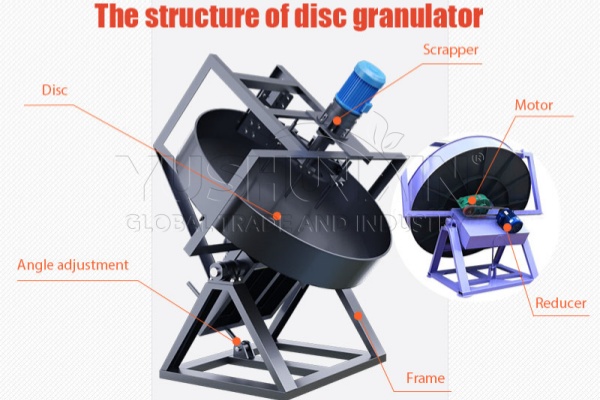

2 Types Shunxin Limestone Pellets Granulating Equipment

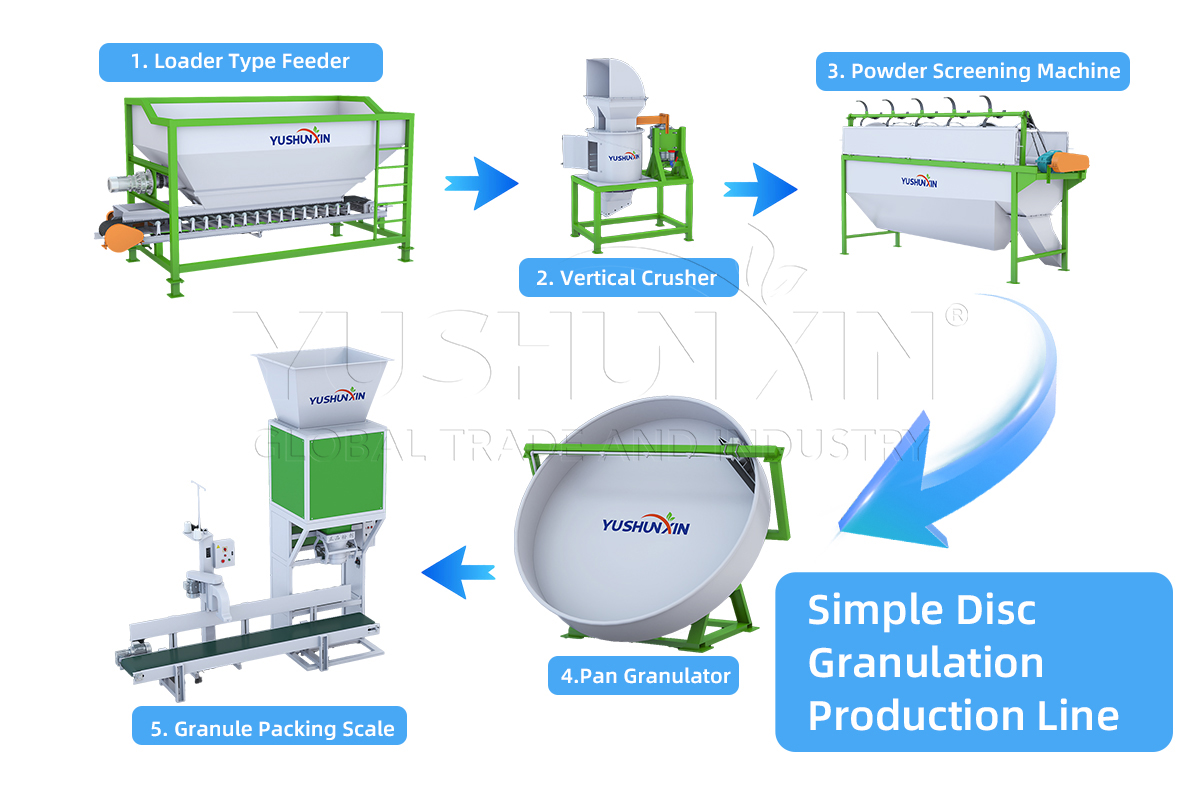

The limestone fertilizer production line is an efficient, environmentally friendly production system is to process limestone raw materials into fertilizer products. Generally speaking, this production line covers the entire process from raw material processing to finished product packaging. This production line can improve production efficiency and reduce production costs. Therefore ensures the final limestone fertilizer quality meets the needs of agricultural applications. The following is the complete working process of the limestone fertilizer production line.