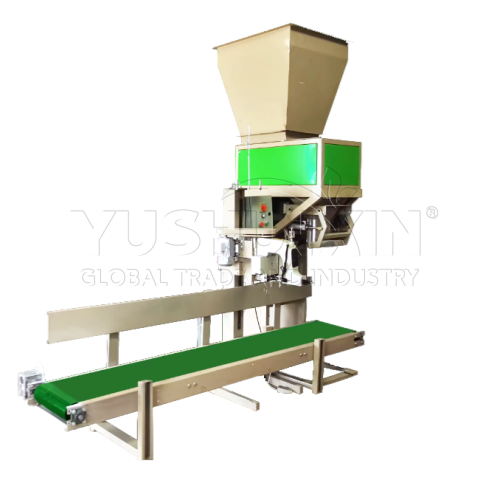

Fertilizer Bagging Machine

Mining, chemical industry, building materials, fertilizer plants, etc.

6 bags/min

0.55+0.37 kw

720×630×1980 mm

In modern agricultural production, fertilizer bagging machine has been widely of use as an important equipment to improve packaging efficiency and quality. Due to its high efficiency, precision and automation, it is of great significance for reducing labor costs. Meanwhile, it improves production efficiency and meeting large-scale production needs.

What are the common types of raw materials suitable for fertilizer packaging machines?

Fertilizer dryer is a kind of equipment specially used to dry the moisture in fertilizer. Moreover, it is widely of use in the production process of organic fertilizer, compound fertilizer and mineral fertilizer. Furthermore, the fertilizer dryer uses hot air to evaporate and remove the moisture in the fertilizer, thereby reducing the moisture content of the fertilizer, improving the storage stability of the fertilizer, and making it easier to transport and use. Then, the following is the working principle of fertilizer dryer:

What are the supporting equipment for fertilizer packaging machines?

In practical applications, fertilizer packaging machines usually need to be in conjunction with a series of related equipment to achieve more efficient and precise packaging operations. The following are some common Yushunxin fertilizer relevant equipment for packaging.

Other Equipment

What is the cost of purchasing fertilizer packaging machine?

The price range of fertilizer packaging machines is wide and affected by many factors. For example, the type of machine (such as fully automatic, semi-automatic), packaging capacity (such as the number of bags packed per hour), the accuracy of the machine, the technology used, the brand and Additional features, etc. Typically, prices can range from a few thousand dollars to hundreds of thousands of dollars.

Firstly, for a small or semi-automatic fertilizer packaging machine, the price may be in the thousands of dollars (approximately $3,000 to $10,000).

Secondly, for a medium-sized automated machine, it could be between $10,000 and $50,000.

Thirdly, for high-end fully automatic packaging production lines, the price may exceed 100,000 US dollars, or even reach hundreds of thousands of US dollars.