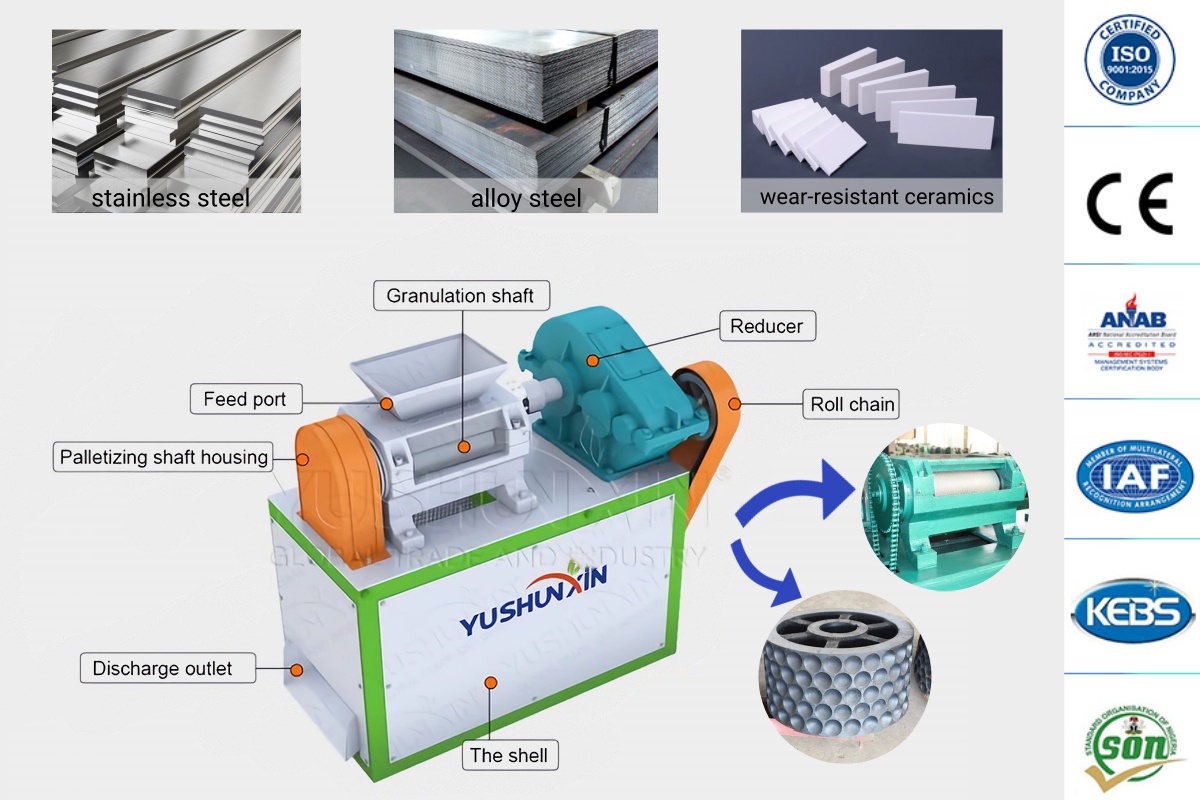

Double Roller Press Granulator

Mining, chemical industry, building materials, fertilizer plants, etc.

1-2 t/h

15-22 kw

3-10 mm

Double roller press granulator, also known as double roller extrusion granulator, is an essential equipment for compound fertilizer granulation. It has the advantages of advanced technology, reasonable design, compact structure, novelty and practicality, and low energy consumption.

Furthermore, this series of granulators, we can customize the shape and size of the ball sockets on the roller skin according to the user’s needs. There is a wide range of shape choices. The ball shapes include pillow shape, semicircle shape, stick shape, pill shape, walnut shape, flat ball shape and square bar shape.

How Does The Double Roller Extrusion Granulator Work?

Our company utilizes external pressure with a double roller extrusion granulator that crushes materials using oppositely rotating round rollers. The motor drives the pulley, and our transmission belt connects through the reducer to two high-pressure rollers with sliding mold shells. Furthermore, we design the two rollers of the extruder with a set of split gears for relative rotation. The two rollers achieve extrusion molding because two output shafts on a special reducer directly drive them.

During production, raw materials enter from the feed hopper, and our process extrudes them through molds on the roller skins. After demolding, they enter the crushing and molding module at the bottom of the roller body. Subsequently, our system breaks the entire particle board into scattered particles, which flow out of the machine. The particles are oblate spherical, resembling apricot kernels. The size of the mold, which we can customize, determines the particle size. Finally, the crushed finished granules pass through the screen to the discharging chute and flow out of the machine.

5 Advantages of Double Roller Press Granulator

Configuration and Selection of Supporting Production Equipment

When you want to use in a complete production process and completing granulation, the matching machines need to have automatic batching systems, material mixers, material conveyors, drum screening machines, automatic packaging machines and other corresponding machines. Specifically, they cooperate with each other to produce all kinds of fertilizers. Generally, you can increase the number of double roller press granulators according to the corresponding output for coordinated production. When producing with a single output, you can replace automatic batching system with a simple silo, and the corresponding material mixer can also be of use optionally.

What Is The Application of Double Roller Press Granulator?

Double roller press granulator is widely adaptable, the raw materials are diammonium phosphate, calcium superphosphate, gypsum, bentonite and other livestock manure waste, etc. The double roller extrusion granulator plays a critical role in the production of compound fertilizers, coal, chemical industry, and metallurgy,etc. Particularly, the double roller press granulator can produce all kinds of high concentration of compound fertilizer, and other kinds of mineral fertilizer, especially potash fertilizer, ammonium nitrate fertilizer and rare earth fertilizer series. Due to its low price, convenient use and maintenance, and easy to operation, thus it is one of the most popular granulators among other equipment. Generally used in small and medium-sized fertilizer plants for granulation production.

What Are The Parameters?

We have 3 types of double roller extrusion granulator that you can choose. Different models vary in capacity and size. The size of the finished particles also ranges from approximately 3mm to 10mm. Our double roller extrusion granulator saves energy and operates with high efficiency, making it the first choice for many mineral fertilizer manufacturers. Additionally, our double roller press granulator offers high efficiency and applicability across various fields. We see its extensive use in many industries, especially in mineral fertilizers. Moreover, our double roller press granulator produces oval pellets. If you require different granule shapes, we offer many customizable shapes and sizes of the ball sockets according to your needs.

Simultaneously, you can match it with corresponding equipment to form a small production line. Thereby, it enables continuous and mechanized production of fertilizers. Furthermore, this equipment adopts an eugenic formula and operates under normal temperature conditions without drying. Consequently, the product rolls and forms in one step, ensuring the product quality meets the technical requirements of compound fertilizer. Moreover, this special compound fertilizer produces high, medium, and low concentrations for various crops.