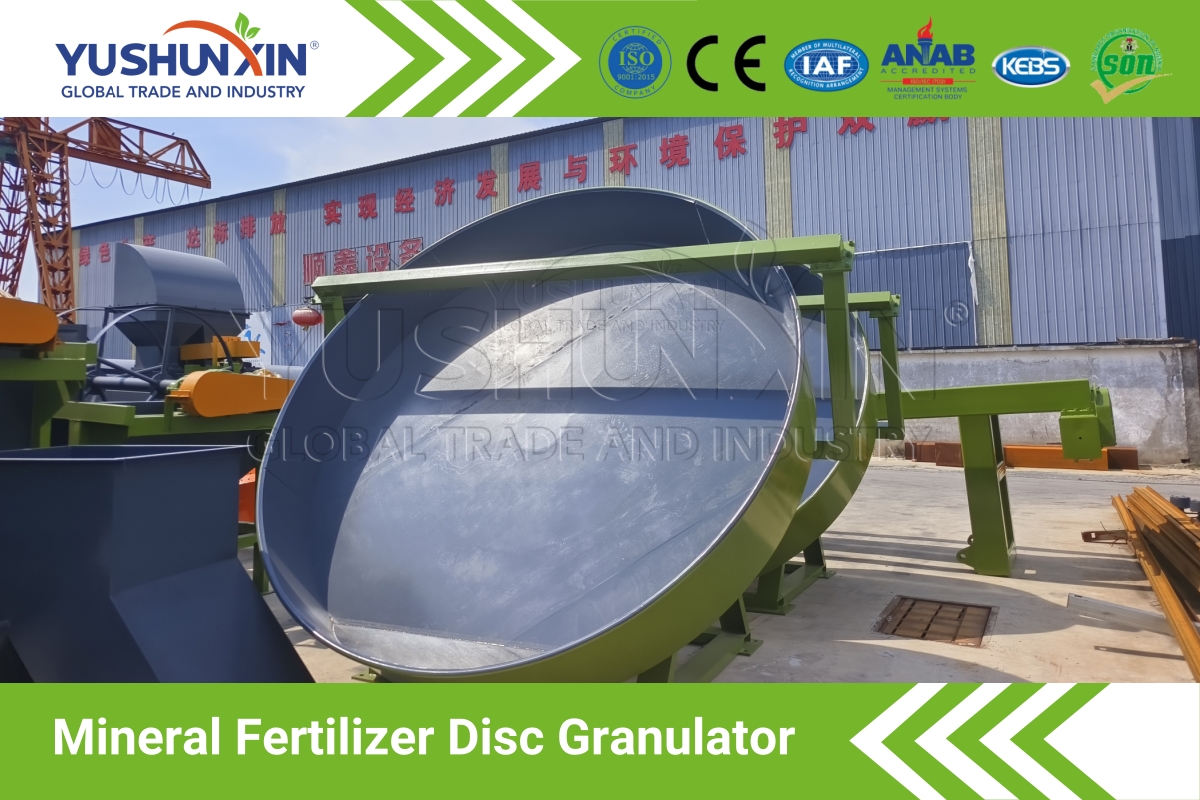

Among the various equipment designed for material granulation, the disc granulator machine is an idealchoice for producing organic fertilizers, compound fertilizers, and other mineral fertilizers. With animpressive granulation rate of 93%, our company have 12 different models, fulfilling diverse needs rangingfrom laboratory scale to small and medium-sized fertilizer production plants. Moreover, the mineralfertilizer granulation capacity varies from 0.02-6t/h, making it adaptable for various industrialreguirements. Whether you are conducting research or running a fertilizer plant, the disc granulator offersa reliable solution for mineralfertilizer production

Mineral Fertilizer Materials Types

What Mineral Fertilizer Materials Can Be Used In A Pan Granulator?

As professional fertilizer equipment manufacturers at Yushunxin, we often receive inquiries from fertilizer producers everywhere about the ideal materials for disc granulator machine. Particularly, the disc granulation process effectively produces uniform and high-quality granules from different mineral materials. Additionally, Our plant specializes in various mineral fertilizer processing machines, including the disc pelletizer, which is pivotal for rock fertilizer production solutions. Here, we discuss the types of materials suitable for pan pellet production and the equipment features that facilitate this process.

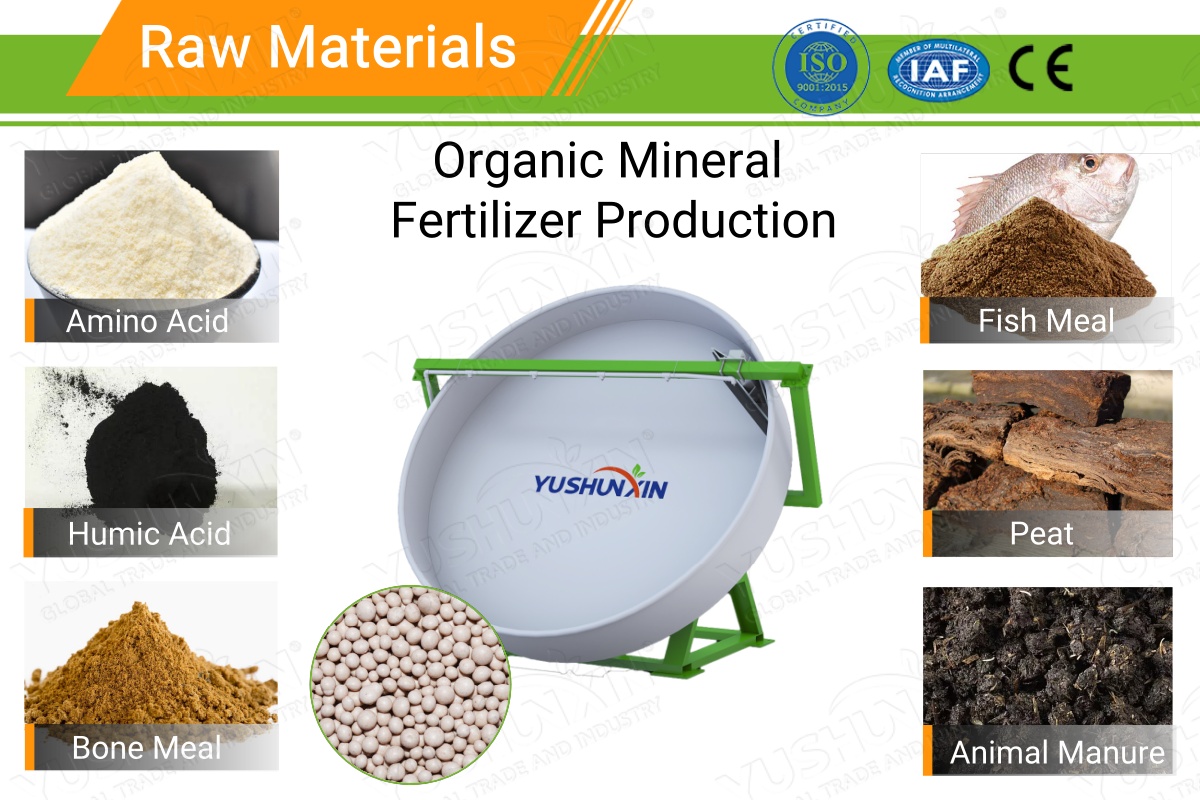

Organic Mineral Raw Materials

To be honest, our company specializes in the production of disc granulator for organic mineral fertilizers. Typically, you can use various organic raw materials in our disc granulators, such as amino acid powder, mineral-source humic acid, animal bone meal, fish meal, seaweed mud, peat, sludge, and animal manure. Besides, you can blend these raw materials in a certain proportion for rich nutrients. Furthermore, due to high moisture of some organic waste, our granulators may need a little water or binders for wet granulation.

The ore fertilizer pellet making process begins with the mixing and rotating of organic materials. Then, disc granulator machine uniformly shapes these materials into granules with the help of its rotating disc. Also, you can consider adding microbial agents to enhance the nutrient profile of the final organic ore fertilizer pellets. Because our pan granulator has agent spraying unit for wet pellet making. Indeed, many customers find that this granulator enable a uniform and high-quality granule output for their organic rock fertilizer granulation.

Relative Equipment

There are many optional equipment for mineral organic fertilizer production includes composting equipment and vertical crusher. First, organic fertilizer composter ensures the raw organic material necessary decomposition and bad germ removal. Composting equipment efficiently processes raw materials such as animal manure, crop residues, and industrial by-products. For instance, we have rail type compost machines, windrow type composters and fermentation pots.

Meanwhile, the new type vertical crusher is very adjustable for handling high moisture organic waste, making it fine for granulation. Moreover, its crushing blades adopt special alloy, so its service life is triple times than other crushers. Together, composting equipment with free options and the vertical crusher play crucial roles in the mineral fertilizer granulation process. They finish the pre-treatment works of organic ore fertilizer raw materials.

3 Types of NPK Mineral Materials

3 Types of Mineral Materials for Disc Granulation to Make NPK Pellets

On the other hand, there are many fertilizer factories that want to produce special fertilizers for flowers, trees, and crops in different growth cycles. And they ask us for such a disc granulator machine for rock compound fertilizer pellet production. Because this equipment can granulate different formulations of NPK powder and other elements.

According to our customers, they mostly purchase powdered materials for ore fertilizer granulation. And they express it is most cost-effective to use a disc granulator. For example, urea, ammonium nitrate, ammonium sulphate, monoammonium phosphate (MAP), diammonium phosphate (DAP), potassium chloride, and potassium sulphate. Because they can save more production costs and quickly get profits. However, some clients who also cooperate in ore mills require other processing equipment to make ores into powder, and then use them to make mineral fertilizer granules. For instance, nitratine, kalisaltpeter, apatite, potassium feldspar, gypsum, carnallite, etc.

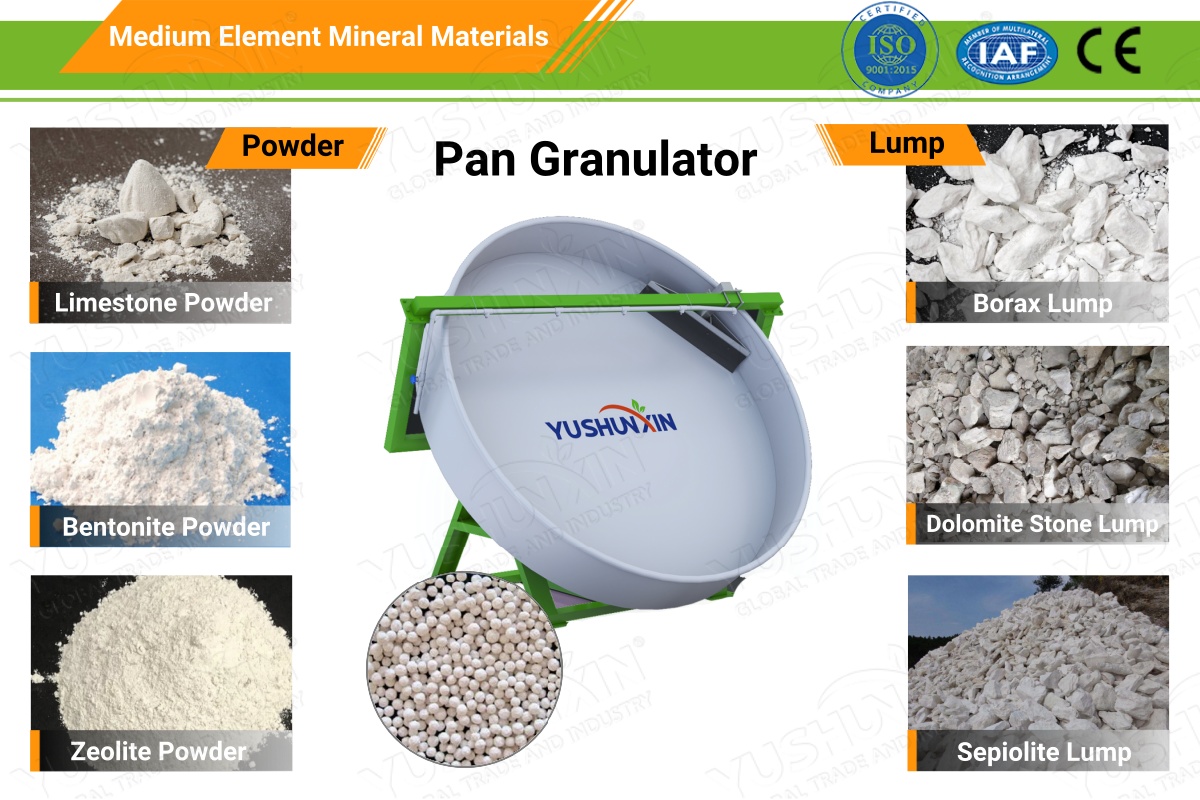

Apart from macroelement, others may use some secondary element mineral materials for rich nutrients or other industrial applications. Typically, they often add extra calcium nitrate, limestone powder, magnesium sulfate, etc. to the pelletizing disc for rock fertilizer granule manufacturing. Furthermore, they use zeolite or bentonite in pan granulator to make cat little particles. Certainly, there are many ores which suit to mineral fertilizer processing, such as gypsum, limestone, borax, dolomite, sepiolite, attapulgite, etc.

Besides, you can also add ferrous sulfate, zinc sulfate, copper sulfate, manganese sulfate powder for disc compound mineral fertilizer granulation process. Also, you may handle medical stone, shell ore, pyrolusite, azurite, malachite into powder to get disc pellet making materials. Whatever, these raw materials can be prepared through physical and chemical processing into compound fertilizer form suitable for various agricultural needs, ensuring that plants can efficiently absorb and use the required nutrients.

Special Crushing Equipment

Together, the jaw crusher and Raymond mill form a powerful combination for ore processing. The jaw crusher’s ability to efficiently break down large mineral chunks makes the initial phase of processing straightforward and effective. Subsequently, the Raymond mill’s fine grinding capabilities ensure that the minerals meet your exact specifications for granulation.

In summary, our plant offers specialized equipment that seamlessly integrates crushing and grinding processes. This enables you to produce high-quality mineral fertilizer granules to your specific needs.

Different Capacity Of Pan Granulators

How To Customize Ore Fertilizer Pan Granulator With Different Capacity?

When considering the efficiency performance of disc granulators in various production scales, we recognize the customization needs of different customers. Hence, you will find our range of granulators ideal for different scales, from small to large-scale manufacturing. We provide customized specifications for your specific requirements, ensuring efficient and high-quality mineral fertilizer granulation.

Yushunxin offers flexible and efficient pan pelletizing solutions for mineral fertilizer granulation across different production scales. Moreover, we provide customizable options to match your specific requirements. Hence, clients can select from a range of diameters, edge heights, rotary speeds, and motor power configurations, ensuring efficient and consistent mineral fertilizer granulation. With various sizes and capacities, our equipment supports your production goals, delivering high-quality granules across different mineral fertilizers.

5-10% Discounts of Buying Disc Granulators

Buying Mineral Fertilizer Disc Granulator Now For 5-10% Discounts!

Our company offers high-quality mineral fertilizer disc granulators to meet various production needs. Whether you require a mini, small-to-medium, or large-scale granulator, we provide detailed specifications and competitive pricing to suit your requirements.

Small

- 0.02-1 T/H Capacity

- 0.55-3 KW

- 21-32 r/min

Medium

- 1.2-3 T/H Capacity

- 3-11 KW

- 14-21 r/min

Large

- 4-6 T/H Capacity

- 11-18.5 KW

- 13-14 r/min

Choosing the right mineral fertilizer disc granulator depends on your specific production needs. From mini to large-scale models, our company provides a range of options with detailed specifications and competitive prices. Take advantage of our 5-10% discount and invest in a reliable granulator today.

Top 2 Special Designs of Pan Granulator

What Make YSX Pan Granulator As The First Choice In Mineral Fertilizer Industry?

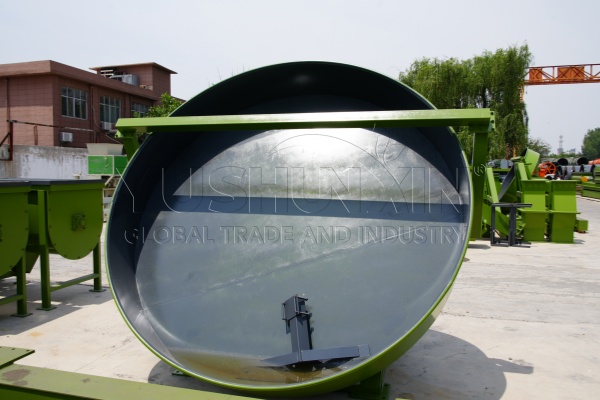

Our company, is a leader in manufacturing high-quality pan granulators for the mineral fertilizer industry. What’s more, we have 20+ years of research and manufacturing experience in fertilizer production equipment. Besides, two special designs in our SXYZ series make them the top choice for professionals: the spray system and effective dust control measures. These designs not only enhance the wet granulation process but also ensure a clean and efficient rock fertilizer production environment.

A Spraying Microbial Agent System

One of the reasons why many customers choose our disc granulators is to install spraying devices. In particular, this design can not only spray water for mineral fertilizer wet granulation process, but also use microbial agents. While manufacturing mineral fertilizer on the rotating disk granulator, you can choose installing such a spraying device. Then, you can achieve a consistent blend of beneficial microbes with mineral fertilizer materials like sodium nitrate and apatite.

The device spraying microbial agent has significant advantages in improving the quality of mineral fertilizer, improving fertilizer efficiency, improving soil environment, reducing diseases and pests, and protecting the environment, so that the production of mineral fertilizer is more efficient and sustainable.

Effective Dust Control Measures

Dust Removal Room Design

Dust control is a critical aspect of the granulation process, and our pan pellet making machines have robust dust control measures. Above all, we design a special enclosed dust removal room. Its cover uses transparent polycarbonate sheet for high strength and durability. Therefore, it not only effectively insulates dust, but also makes workers easy to observe the inner workings through transparent materials.

Water Spraying Device

Secondly, our engineers can install water spray devices inside or around the pan granulation machine. So this inhibit the diffusion and settlement of dust by spraying water mist. In addition, our disc granulators are equipped with negative pressure air extraction devices. By forming a negative pressure environment in the dust cover, the air fan quickly absorbs the dust into the dust collection system.

Dust Collection System

Thirdly, we also have extra measures. Ventilation ducts above the granulator are usually made of corrosion-resistant PVC or metal. Indeed, we use efficient seals of rubber or silicone materials at the joints of the pelletizer and the dust collection system. Furthermore, you can choose to install dust collector in this room, like bag type or cyclone dust collector. As a result, it can automatically and effectively collect and filter dust from the pelletizer operation.

In conclusion, the disc granulator is an essential machine in fertilizer granulating, and it’s also a priority for many mineral manufacturers to choose. The granulated pellets are both good in shapes and mineral fertilizer efficiency. We have different modes of them vary in capacity and diameter of discs. More importantly, you are welcome to customize the disc mixer as your requirements as well.