Clay Soil Granules Machine

Mining, chemical industry, building materials, fertilizer plants, etc.

1-30 t/h

7.5-22 kw

3-10 mm

Zhengzhou Shunxin Engineering Equipment Co., Ltd. is the leading brand of fertilizer equipment in China. Our company’ s main business projects are the installation and production of fertilizer equipment, extrusion equipment, granulation equipment, drying equipment, mechanical equipment and accessories, and the design and construction of fertilizer engineering. And among other fertilizer equipment manufacturers, we have various specifications of granulators can meet almost all customer’s requirements. Therefore, if you are looking for a clay soil granules making machine. Besides, we can provide the suitable pelletizer for you to meet your needs.

What is clay soil pelletizing machine?

Clay soil pelletizer is a kind of equipment specialized in pelletizing clay soil raw materials. Moreover, it is widely of application in the fields of ceramics production, horticultural soil conditioner preparation, and environmental engineering. Clay soil pelletizers can be of use to improve productivity and product quality. Thus, it increases their applicability and effectiveness in a wide range of applications. These machines typically include a mixing and blending system to blend the clay and other additives. Then, the mixture is pressed into pellets by means of a die or extrusion mechanism.

4 Applications of clay soil pellets

Top 3 High Efficiency Clay Soil Granulators

Rotary Drum Granulator

Rotary drum granulator is the core machine of a clay soil granulation production line, which is suitable for large-scale production. It adopts the wet method of agglomeration granulation, through a certain amount of water or steam, making the fertilizer in the cylinder body humidification after the full chemical reaction. With the rotary movement of the cylinder, the material is agglomerated into balls. Additionally, if you use this kind of equipment for granulation, you may need to equip a fertilizer drying and cooling machine for your clay soil pellet production line. Of course, we have suitable dryer and cooler for your use.

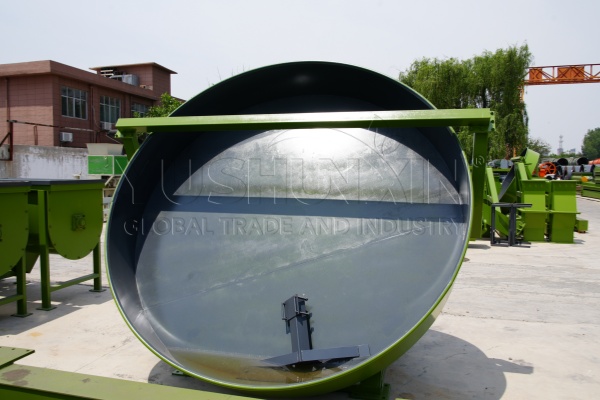

Disk Pelletizer

Clay soil disc granulator is a highly efficient granulating equipment, which is popular for small and medium scale granules production. Indeed, it has three discharge ports on this granulator, which can realize continuous production and greatly improve the production efficiency. It not only has the simple structure and flexible operation, but also has a high granulation rate of more than 93%. For this reason, it is an ideal machine for many mineral fertilizer manufacturers because of its high efficiency.

How to make clay soil pellet during the granulating production line?

How To Form A Complete Production Line For Clay Soil Granules?

If you want to assemble your clay soil pelletizing production line, Shunxin Machinery Fertilizer Equipment Company can fully meet your needs. In fact, we have various types of fertilizer equipment. And a complete pelletizing production line usually includes material crushing, mixing, granulating, drying and cooling, screening, coating, packaging and other processes. The following are the main equipment and processes of clay soil pelletizing production line.

Do You Know Why Make Clay Soil Into Granules?

Clay soil is a kind of sandy clay with a variety of minerals, and its main components are silicate minerals, mica and diatoms. Clay soil granulation is the clay material through the granulation equipment processing into a certain shape and size particles. Furthermore, clay soil granulation not only enhances its suitability and effectiveness in multiple application fields, but also improves the physical properties of the material, such as increasing strength, improving air permeability and so on. Accordingly, this process will inevitably use the clay granulator, which can process the clay powder into granular materials. Especially, this process will directly affects the quality of the finished product. Owing to the variety of ways to make clay granules, including roller granulation, extrusion granulation methods. Definitely, we have different granulating machines that are suitable for different product requirements.