Bentonite Granules Making Machine

Mining, chemical industry, building materials, fertilizer plants, etc.

1-6 t/h

4-22 kw

3-10 mm

Bentonite granulator is a device that converts bentonite or bentonite mixture into granular materials. Through the processing of bentonite ferilizer granulator, the raw bentonite materials can become uniform small granules. It will not only facilitates storage and transportation, but also be more convenient to adjust the size, shape and density of the particles. Hence, it is necessary for you to choose a suitable bentonite fertilizer granulator. Our company has many high quality and performance fertilizer production machines. No matter what granulation equipment you want, we can always meet your needs. Moreover, we also have complete processing fertilizer production equipment lines, where you can have a complete set of fertilizer production equipment.

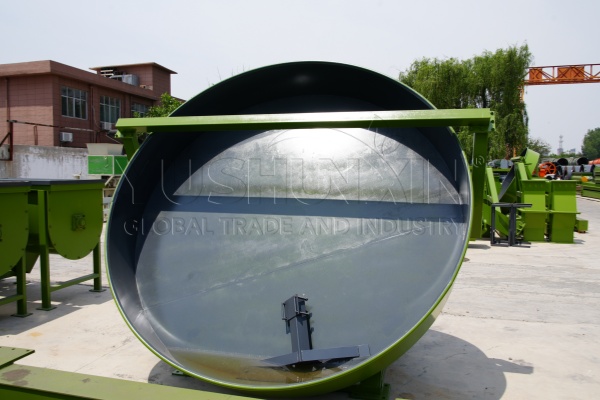

How Does The Pan Granulator Equipment Make Bentonite Powder Into Granules?

After preliminary processing, the raw bentonite is then send into the disc. The rotation of the disc generates centrifugal force, causing the raw bentonite materials to be granulated. At the same time, the scraper inside the disc scrapes the raw materials from the edge of the disc into particles. With the continuous rotation of the motor, bentonite materials continue to enter, the raw bentonite materials are evenly bonded together to produce high-quality bentonite granules. When the disc’s inclination angle, disc edge height, rotation speed and moisture content are constant, the balls of different particle sizes leave the edge of the disc. And they will roll downward at different breakaway angles due to different gravity. Afterwards, the granules after classifying and screening through the screen. And then they discharge from the edge of the plate as the tilt plate rotates. Finally, you can obtain the required bentonite fertilizer particles. With the continuous rotation of the motor, materials continue to enter, and mass production can be achieved. Meet user needs.

What Are The Necessary Processes Before Bentonite Granulation?

There are 2 essential processes before bentonite granulation, which can make the bentonite raw material to reach a suitable size for granulation, thus improving the efficiency of granulation. Following are the 2 necessary processes before bentonite pulverizing.

Crushing process

Pulverizer machine plays an important role in the process of fertilizer production. It can grind large pieces of bentonite materials into the desired size for pelletizing. Through this way can get a uniform size of bentonite particles, which helps to improve the subsequent granulation efficiency and quality. Therefore, choose a appropriate crusher is essential, our company provides many types of crushing equipment, such as new vertical crusher and semi-wet material crusher for bentonite fertilizer granulation production. You can click the links and jump to the detail page of the related pulverizing equipment.

Mixing process

During the production of bentonite granulation, you may need to add other organic materials or sodium carbonate, sodium silicate and other ingredients to improve the effect of bentonite fertilizer. Then you will need a bentonite mixer to thoroughly mix these ingredients. Homogeneous mixing helps ensure consistency and quality of the final bentonite fertilizer pellets. We have several sophisticated bentonite mixers that you can choose from, such as horizontal mixer, double shaft horizontal blending machine. Whatever you want for a bentonite granulation production line, we can fully meet your specific needs. If you are interested or want to consult anything else about your plant, you can click into the detail page of this equipment to know more about it.

What Are The finished fertilizer’s Different Applications of Bentonite Granules Making Machine?

- Soil amendment

Granular bentonite is effective in improving the physical properties of the soil. It helps increase the porosity of the soil, thereby improving its permeability and water retention. This is especially effective in sandy and clayey soils as it promotes healthy root development, which improves overall crop growth.

- Fertilizer conditioner

Bentonite can be of use as a fertilizer conditioner in the process of compound fertilizer production. Adding a small amount of bentonite in the fertilizer, it can not only reduce the water content of the fertilizer, but also prevent the fertilizer agglomeration. Therefore, it produces bentonite fertilizer with uniform particles and good properties. In addition, bentonite also has the ability to maintain the effect of fertilizer, which is conducive to the delivery, preservation and use of fertilizer.