What Are Common Materials for Nitrogen Ore Fertilizer Manufacturing?

Firstly, Nitrogen is crucial for plant growth, playing a significant role in the synthesis of proteins and other compounds. For the production of nitrogen fertilizers, materials like natural sodium nitrate (NaNO₃) and calcium nitrate (Ca(NO₃)₂) are popular choices. Typically, you can process them into fine particles using a jaw rock crusher, ensuring uniformity and effectiveness in the further fertilizer processing.

Alternatively, for reducing production costs, you can purchase powdered forms of urea and ammonium nitrate. Then, you may use the pan granulation machine to transform these materials into granular Nitrogen fertilizers, ensuring uniform nutrient distribution.

How to Choose Raw Materials for Making Phosphorus Rock Fertilizer?

Secondly, phosphorus fertilizers are essential for root development and flowering in plants. For example, you can select apatite (Ca₅(PO₄)₃(F,Cl,OH)) as the raw materials, which undergoes extraction and processing to produce fine particles. Hence, it’s wise to use the mineral fertilizer crushers.

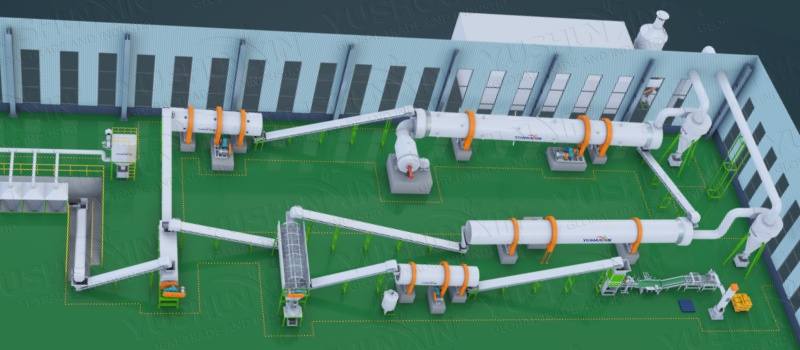

Other materials include superphosphate and diammonium phosphate (DAP) powder. Besides, you can directly get mineral fertilizer granules in a large scale by rotary drum granulator. So, you can convert raw phosphate rocks into fertilizers by applying our rock phosphate fertilizer production line.

How Can You Produce Potassium Fertilizer Ore Granules?

Thirdly, potassium is crucial for overall plant water regulation and disease resistance. On one hand, you may handle potash, potassium feldspar, or mica to produce fine granular potassium fertilizers by ore fertilizer crusher machine. Additionally, you can use potassium sulfate (K₂SO₄) and potassium chloride (KCl) powder commonly. Meanwhile, our granular potassium fertilizer equipment ensures that these materials are adequately processed into granular ore fertilizers with high granulation rate and low energy consumption.

What Are Trace Elements for Mineral Fertilizer Production?

Fourthly, trace elements are vital for specific plant functions. The production of ore fertilizers involves various resources as the primary raw materials. These resources include:

- Calcium Minerals: Such as gypsum, calcite, and siliceous limestone;

- Boron &Magnesium Minerals: Like borax, boromagnesite, tourmaline and dolomite;

- Silicon Minerals: Such aszeolite, quartz, pumice, and attapulgite, etc.

In fact, many mineral fertilizer manufacturers also widely use natural mineral fertilizers in this industry like maifan stone, vermiculite, bentonite, and diatomaceous earth. Furthermore, they discover new varieties of mineral fertilizers, including silica, rare earth, peat, and serpentinite fertilizers. Honestly, we have many granulators for your choice to make mineral fertilizer, like bentonite granulator, zeolite powder granulator, clay granulation machine or double roller extruder pelletizer.

What Materials Can Be Used in Organic Mineral Fertilizer Management?

Finally, organic-based mineral fertilizers combine the benefits of organic matter with mineral nutrients, enhancing soil health and fertility. For instance, you can use livestock manure, crop straw, peat, and humic acid. In addition, you need to mix these organic materials with mineral components using mineral fertilizer mixer. If it’s possible, you also need a drum dryer to reduce moisture in ore fertilizer. What’s more, you can contact us to customize personal mineral organic fertilizer production lines to ensure consistent and efficient processing.