No. 1 Method of Dust Control During Compound Fertilizer Pre-treatment

Dust control is crucial during the dynamic batching of NPK compounds. And, this stage involves mixing various raw materials such as rock phosphate, potash ore, and nitrogen compounds. Without proper dust control, fine particles can escape into the air, causing pollution and health hazards. Yushunxin provides baghouse dust collectors that can be installed beside dynamic batching machines. Then, these collectors capture dust particles, ensuring a cleaner production environment.

Another effective method to reduce dust during is to add water to the mixture. Additionally, this can be done using a horizontal mixer. Moreover, adding water helps to lower dust levels and makes the materials easier to handle. This method not only reduces dust but also enhances the mixing process, resulting in a more uniform product. By using these techniques, you can significantly reduce dust emissions during the batching stage.

No. 2 Method of Dust Control By Protective Equipment

Material transmission is another critical point where dust control is necessary. Beside, conveyor belts and screening machines can generate significant amounts of dust. To address this, our plant offers dust-proof covers for conveyor belts and screening machines. For example, when raw minerals like rock phosphate and potash ore are transported via conveyor belts, dust can be generated. Thus, these covers prevent dust from escaping into the air and ensure that the working environment remains clean. By using dust-proof covers, you can effectively control dust emissions during material handling. In addition, this not only improves air quality but also enhances the efficiency of your production process.

No. 3 Method of Dust Control By Specialized Dust Removal Equipment

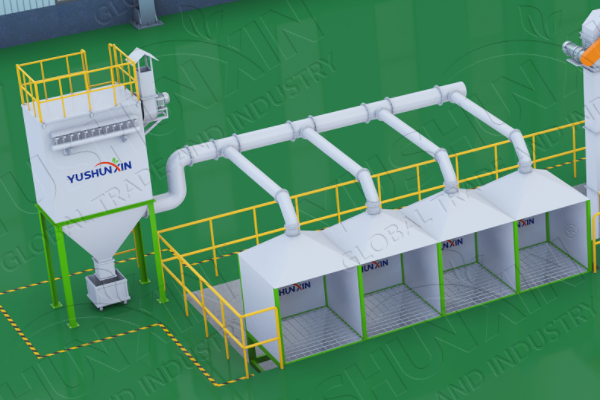

During the granulation process, particularly when using a disc granulator, dust can be a significant issue. Our company offers specialized dust removal equipment tailored to this stage of production. One effective solution is the dust collection chamber, which encloses the disc granulator, capturing dust as it is generated. This method not only controls dust but also improves the quality of the final fertilizer product.

In addition to conventional cyclone dust collectors, we provide advanced pulse jet dust collectors. These devices are highly efficient at removing fine dust particles from the air. The pulse jet system uses short bursts of compressed air to clean the filters, ensuring continuous and effective dust removal. This advanced technology is particularly beneficial when processing minerals that tend to generate fine dust, such as potash ore and phosphate rock.