What Mineral Raw Materials Are Used for Fertilizer Granulation?

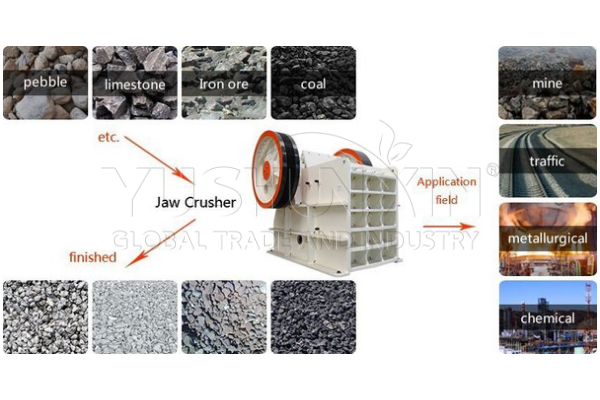

In the production of fertilizers, a wide array of mineral raw materials can be of use for granulation purposes. Commonly, these materials include limestone, calcite, barite, dolomite, potassium feldspar, marble,talcum, gypsum, kaolin, bentonite, medical stone, rock phosphate, iron ore, quartz, active carbon, coal, etc. For one thing, if the raw materials are hard solids, you must crush them in a powdered form. Conversely, if you already procure ore powder, you can directly feed them into a powder granulation machine to produce the desired granular fertilizer products.

How to Prepare The Mineral Raw Material for Fertilizer Production?

At the beginning, you should pay attention to prepare raw mineral materials. Because this step is crucial, as the quality of the granules heavily depends on the consistency and size of the initial material. In addition, the preparation involves two critical steps: crushing and milling.

How Are Mineral Powders Transformed Into Granules?

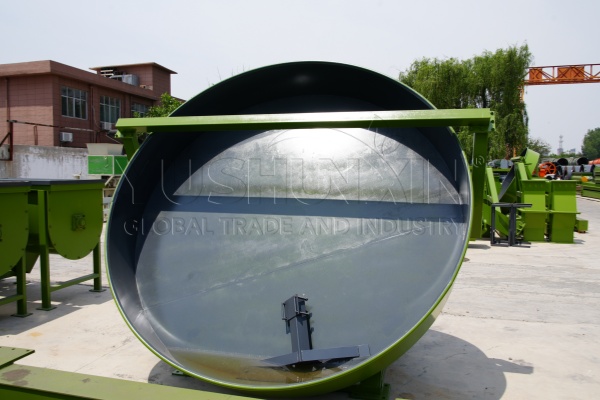

Transitioning from fine mineral powder to granules is where the magic happens. This transformation requires precise control and the right equipment. Two types of granulators are primarily used for this purpose: the disc granulator machine and the rotary drum fertilizer granulator. Each of these machines has its unique method of granulation, yet both are capable of producing 3 to 4 mm sized granules.

The disc granulator uses a rotating disc to agglomerate the mineral powders into granules. Through adjustment, one can control the size of the granules. On the other hand, the rotary drum fertilizer granulator utilizes a slightly different approach, where the mineral powder is fed into a rotating drum, and the motion within the drum forms the granules. This method is particularly effective for achieving the desired 3 to 4 mm granule size.

Why Is Screening Necessary After Granulation?

After granulation, not all granules will be of the required size. Here, the screening machine plays a pivotal role. It separates the granules into the desired sizes, ensuring consistency and quality. The granules that are too large can be crushed and regranulated, while the too small ones can be reprocessed, ensuring minimal waste and maximizing efficiency.

Indeed, the post-screening phase is not the end. Double roller press granulator often comes into play to enhance the granules’ hardness and shape, making them more suitable for sale and application. This step ensures that the granules are not only of the correct size but also have the physical properties required for easy handling, storage, and application.