Which granulator do we recommend to meet the Mexican company’s 5T/H NPK compound fertilizer production needs?

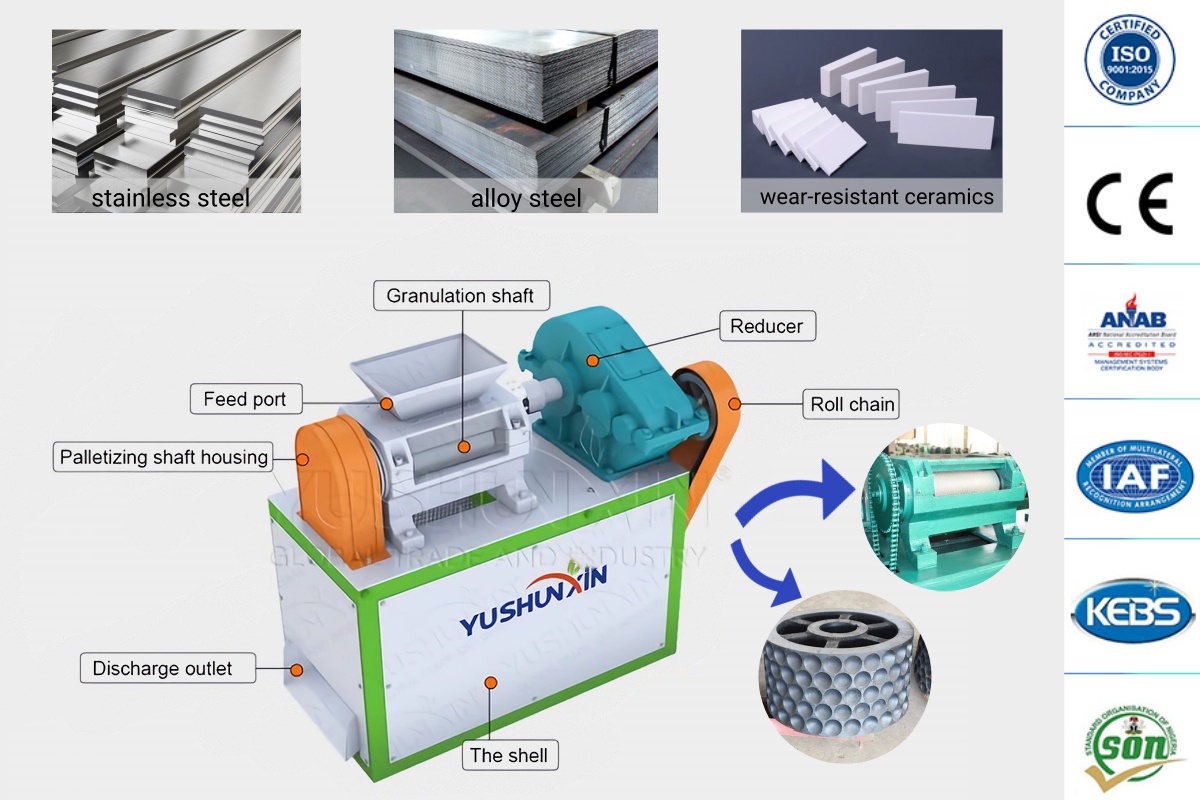

The double roller extrusion granulator is commonly of use in NPK compound fertilizer granulation production lines. Its main feature is to use physical pressure to squeeze materials into particles. It is suitable for directly pressing dry powdery materials into granules without adding wetting agents and other auxiliary ingredients. Therefore, Yushunxin double roller extrusion granulator has the advantages of energy saving, emission reduction and production efficiency improvement. It can efficiently and continuously complete the granulation needs.

How to automatically package finished NPK compound fertilizer granules?

Yushunxin fertilizer bagging machine is the final process of the NPK compound fertilizer granulation production line. It is an important equipment to improve the packaging efficiency and quality of the entire production line. Due to its high efficiency and high degree of automation, it can reduce labor costs, improve production efficiency, and meet the requirements of continuous production. For these reason, we recommend you equip a SX fertilizer bagging machine in your manufacturing plant.