Part 1: Why Is the Disc Granulator Machine a Top Choice?

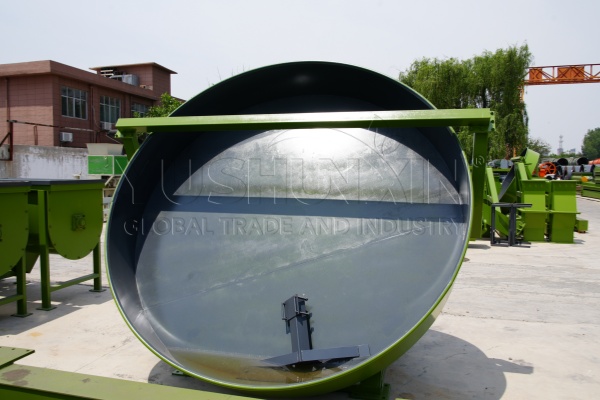

The disc granulator machine is popular for its simplicity and efficiency. Also, it is designed to handle various mineral materials, making it a versatile choice for mineral powder granulation. The machine’s adjustable disc angle and uniform granulation process ensure high-quality output, making it a hot seller in 2024.

Moreover, the disc granulator machine works by rotating a disc filled with the processed mineral materials. The rotation creates a centrifugal force that forms granules through agglomeration. This process is efficient and produces uniform granules ideal for various production lines, such as limestone fertilizer production and rock phosphate fertilizer production. At Yushunxin, we ensure our disc granulators are durable and provide consistent performance, making them a reliable choice for your production needs.

Part 2: What Makes the Rotary Drum Fertilizer Granulator Popular?

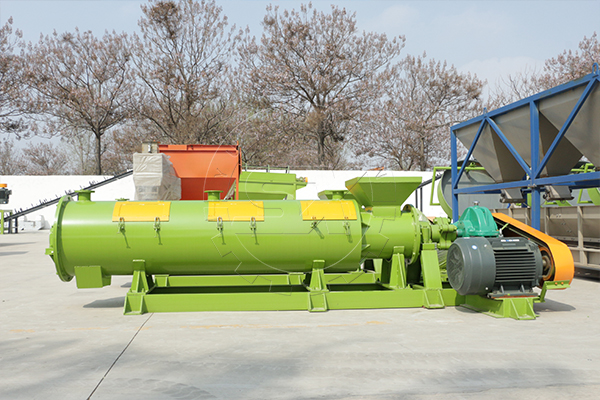

The rotary drum fertilizer granulator is favored for its high production capacity and efficiency. It is suitable for large-scale operations and can handle a wide range of mineral materials. This machine is particularly effective in converting mineral powder into uniform granules, making it a best-seller in 2024.

The rotary drum fertilizer granulator operates by rotating a drum filled with the mineral materials. As the drum rotates, the materials agglomerate into granules. This machine is compatible with various production lines, including NPK fertilizer manufacturing and mineral organic fertilizer production. Its ability to handle large volumes efficiently makes it an essential part of any large-scale production operation. At Yushunxin, we offer rotary drum granulators that ensure high productivity and low maintenance.

Part 3: Why Is the Double Roller Press Granulator in High Demand?

The double roller press granulator is known for its ability to produce high-quality granules without the need for drying processes. This feature makes it energy-efficient and cost-effective, contributing to its high demand in 2024. The machine’s compact design and high output make it suitable for various production scales.

The double roller press granulator works by compressing mineral materials between two counter-rotating rollers. This compression forms uniform granules, which are then ready for use. This granulator is particularly useful for bulk fertilizer blending plants and rock phosphate fertilizer production. At Yushunxin, we provide double roller press granulators that ensure consistent performance and high-quality output, making them a reliable choice for your production needs.

Part 4: What Sets the New Vertical Organic Fertilizer Granulator Apart?

The new vertical spiral granulator is a cutting-edge addition to our range of granulator machines. It is designed to provide high efficiency and flexibility in processing mineral powder into granules. Its innovative vertical spiral design allows for continuous granulation, making it a hot seller in 2024. The vertical spiral granulator operates by feeding mineral powder into a vertical chamber where a spiral mechanism continuously forms granules. This design enhances the granulation process, ensuring uniform size and high-quality granules. The machine is suitable for various production lines, including mineral organic fertilizer production and mine waste management. At Yushunxin, we ensure the vertical spiral granulator meets the highest standards of efficiency and reliability, making it an excellent choice for modern production facilities.