Which equipment can meet the needs of 3 t/h mine powder granulation production line?

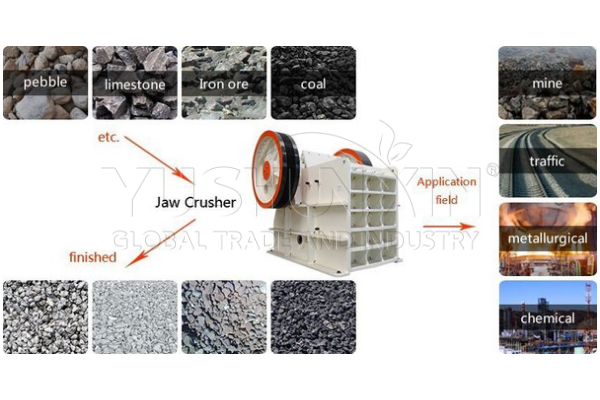

Mineral crushing is an integral part of the entire granulation process.The main purpose is to crush the ore raw materials into fine particles suitable for granulation. Since ore crushing is not completed in one go, the process involves multiple steps, from coarse crushing to fine grinding, ultimately forming mineral powder suitable for granulation.