Mine Waste Management

Mining, chemical industry, building materials, fertilizer plants, etc.

1-30 t/h

7.5-22 kw

3-10 mm

In the process of mining and utilization of mineral resources, it is inevitable to generate a large amount of ore waste. Waste rock is a kind of solid waste, including ore gravel, slag, waste ore, tailings, etc. If these ore wastes are not properly disposed of, they will have a serious impact on the environment.

Mine waste management is an integral part of the mining process of mineral resources. It involves the effective treatment and disposal of various wastes generated during the mining process, thereby reducing pollution and damage to the environment. With the improvement of environmental awareness and the strict implementation of relevant laws and regulations, mine waste management has become one of the key factors for the sustainable development of the mining industry.

Why the importance of ore waste treatment

To begin with, the accumulation of waste will occupy a large amount of land resources and pollute the land. Secondly, waste contains a large amount of toxic and harmful substances. If it is discharged without any treatment, it will cause harm to the surrounding environment and human health. Therefore, you cannot ignore the importance of mine waste treatment.

These wastes, if not handled properly, will not only pollute the environment. But it may also have serious impacts on soil quality, water quality and so on. Therefore, it is crucial to effectively manage ore wastes by adopting appropriate treatment methods and measures, such as recycling and safe landfilling.

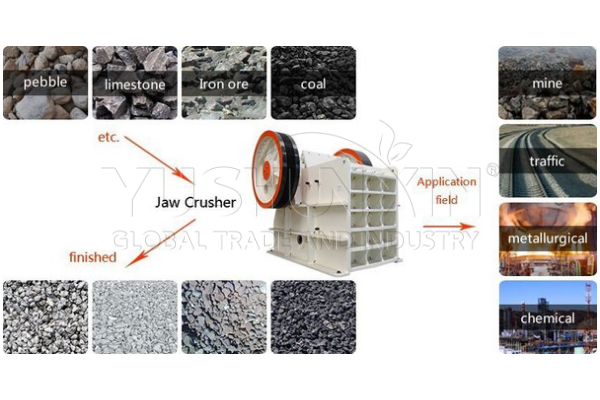

Hot selling mine crushing machine and auxiliary equipment

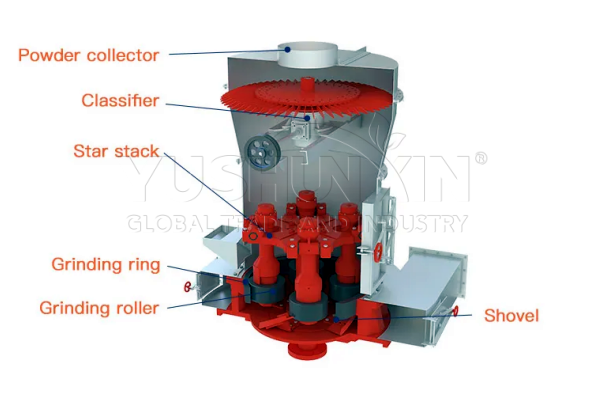

Raymond Mill For Sale

Raymond mill is of use for high-precision processing of coarsely crushed materials. Its working principle is to put the crushed phosphate mineral materials into the grinding chamber and grind them repeatedly under the pressure between the crushing roller and the grinding disc. Shunxin Raymond Mill has the characteristics of high crushing efficiency, low energy consumption and adjustable crushing particle size.

What does the process of mine waste treatment include?

Mine waste treatment and resource utilization play an important role in the mining industry. Meanwhile, it not only reduces environmental pollution but also recycles valuable substances. Therefore, it is necessary to use a series of processing equipment to process these ore wastes. The following is the main steps of mine waste processing.

What are the functions of processed mine waste?

Why is the role of pulverization so important in the ore waste treatment process

The comminution step plays a crucial role in the mine waste treatment process. Moreover, the main objective of this step is to further crush the mine waste into smaller particles for subsequent processing or utilization.

Through pulverization, the contact area between the mine waste and the chemical reagents is significantly increasing. Hence, this helps to accelerate the chemical reaction process, improving ore utilization and reaction efficiency. In addition, the crushing step enables the classification and grading of ore waste. Ore wastes with different particle sizes have different values and uses in subsequent treatment or utilization processes. Effective utilization and maximization of resources can achieve through crushing process.