Carbon Black Granulation Plant

Mining, chemical industry, building materials, fertilizer plants, etc.

1-30 t/h

7.5-22 kw

3-10 mm

Carbon black, is a black powder or particle mainly composed of carbon atoms. Due to its unique physical and chemical properties, it plays an important role in multiple industry sectors. Specifically, it is widely used in rubber, plastics, inks, coatings, electronic components, leather chemicals, dry batteries and many other industries. Carbon black is a type of fine carbon particles, which is made by burning or pyrolyzing carbonaceous materials in the absence of oxygen. Actually, it has the charcteristics of good conductivity, pigmentation and reinforcing properties. What’s more, carbon black can not only improves the mechanical strength and service life of products, but also provides better color and gloss.

3 types of Shunxin carbon black pelletizing machine

There are various types of carbon black granulators, and clearly different types of granulators are suitable for different granulation methods and production scales. Here, Shunxin has the following 3 types of granulators for you to choose for your carbon black pelletizing plant.

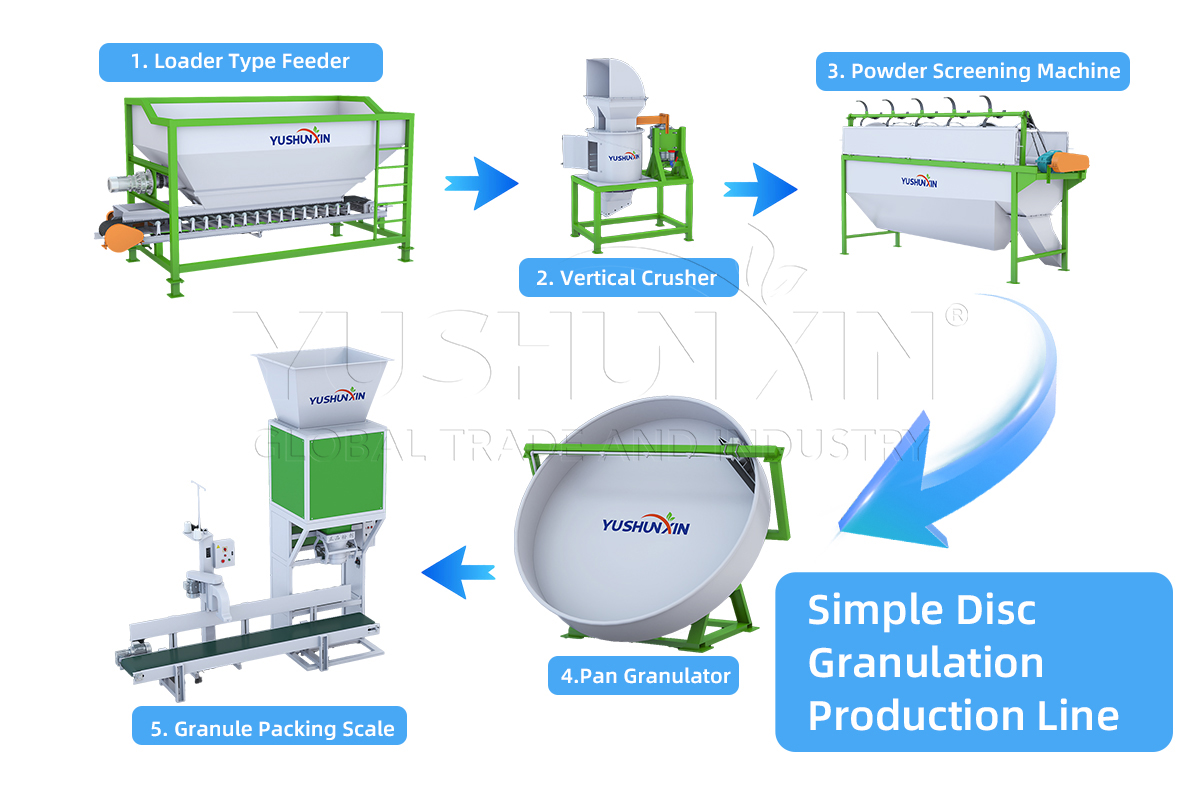

What is carbon black granulation production line

The carbon black granulation production line is a set of equipment that converts carbon black powders into pellets. Generally speaking, the complete production process mainly includes raw material preparation, crushing, mixing, pelletizing, drying and cooling. Among which, the most important process is pelletizing process. These processes not only require precise control of various parameters to ensure product quality, but also take into account economic factors such as production efficiency and energy consumption.

In the production of carbon black, the granulation is the key process in the entire granulation production line. In brief, the application of carbon black granulation technology not only solves environmental and health and safety issues, but also improves material utilization and reduces transportation costs. For these reasons, a complete equipment of the carbon black granulation line is very important.

2 carbon black granulation production methods

Carbon black, as a widely used synthetic material, it has important industrial value and diverse uses. In the production process of carbon black, the two main granulation methods are dry method and wet method. Particularly, the dry granulation method is known for its high efficiency and low cost, while the wet granulation method has been favored because of its more flexible and environmentally friendly characteristics. Following are the detailed introduction of 2 granulation methods:

Carbon black dry granulation method

Granulation principle

Carbon black dry granulation method is a commonly used method. It is the process of converting carbon black powders into granules under dry conditions. Generally, this process does not need to add water or other binders, thus calling it as dry granulation method.

Granulation characteristics

- High efficiency: The carbon black dry granulation method can quickly turn the powder materials into pellets. Because the reaction time is very short, then has the advantages of simple operation and high production efficiency. Therefore, it is more suitable for large scale production.

- Low cost: By using this type of granulatuion method, there is no need for additives and other adhesives. Therefore, the production cost is relatively low, so it is suitable for plants with low cost budgets.

- High purity: Since there is no need to add water or other solvents, the carbon black finished pellets always have high purity and stable quality.

Application fields

Carbon black dry granulation method is widely used in rubber products, plastic products, printing inks and other fields. Due to its high pellets purity and controllability, making the carbon black have good application prospects in these fields.

Carbon black wet granulation method

Granulation principle

Carbon black wet granulation method is through adding appropriate amount of water or other liquid binder to turn the carbon black powders to form ball-shaped particles. Different from dry granulation methods, the finished pellets after wet pelletizing have a high water content, so it will need a dryer to dry out the moisture, and then use a cooler to cool down the temperature. Finally, you can get uniform carbon black granules.

Granulation characteristics

- Controllable particle size: Using the wet granulation method, the size and shape of finished particles can be controlled, and you can easily get regular shape and uniform particle size.

- Wide adaptability: Wet pelletizing method can adjust the type and dosage of binder to adapt to different properties of carbon black and different application requirements.

- Eco-friendly: Through the wet granulation treatment, the flying of carbon black dust can be reduced. Considering from the perspective of overall environmental protection, the wet method can better control and dispose the waste water and exhaust gas when processing.

Application fields

Wet granulation method of carbon black is widely used in coating, ink, cosmetic and other industries. The adjustable pellets of wet carbon black enables it to realize more application potential in these industries.

What is the process of carbon black production line?

In conclusion, Shunxin have many powder granulator machines for you to choose, used to improve the processing efficiency and improve product quality. If you want to make the right choice and application of pelletizing machine, then there is necessary for you to consider the material characteristics, working efficiency, particle requirements and many other factors. Consequently, you will set up a satisfactory automatic fertilizer powder granulation production line.