Jaw Crusher

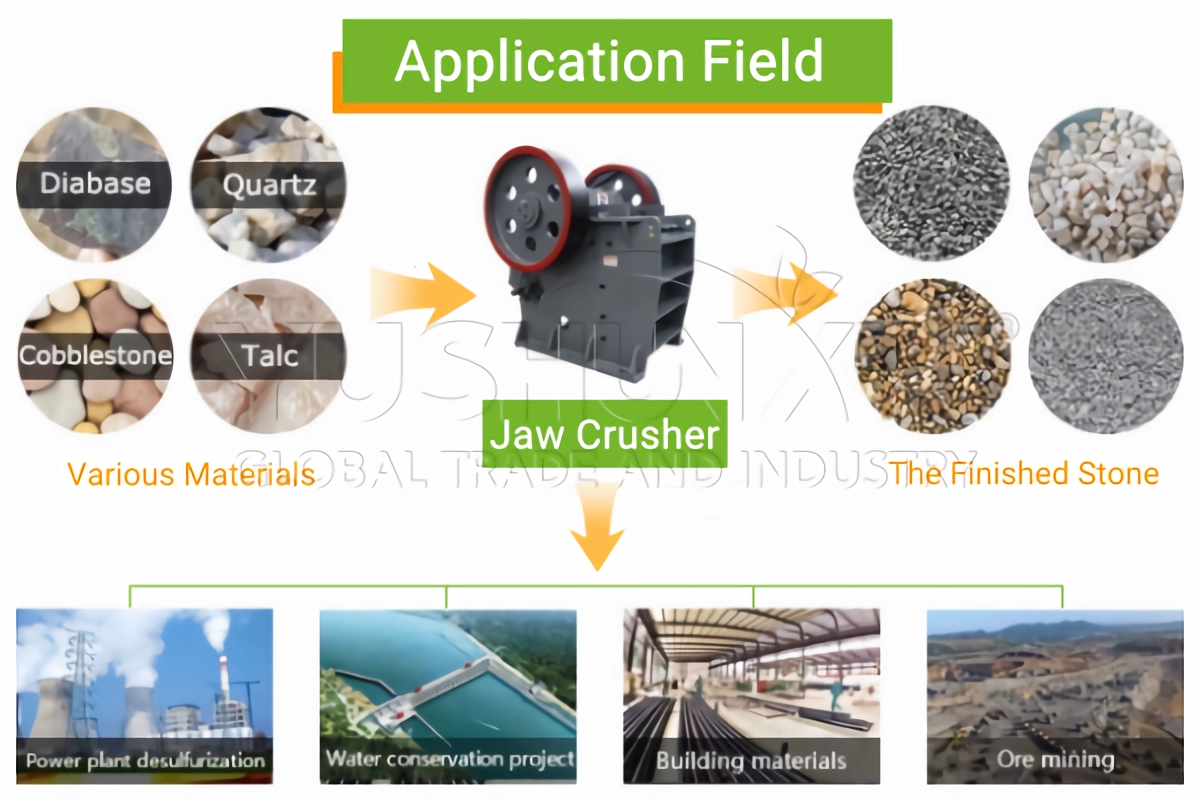

Mining, chemical industry, building materials, etc.

1-60 T/H

5.5-75 kw

15-90 mm

A jaw crusher is a powerful and efficient type of grinding machine in mine and ore processing plants to crush rocks into smaller pieces. In a variety of crushing equipment, it stands out as a primary choice for many mineral fertilizer processing manufactures. Moreover, the jaw shredder could process large pieces of rock or ore and crush them down to smaller sizes. In deed, it is popular with its simplicity, durability, and efficiency. Thus, the jaw crushing machine becomes an indispensable equipment that plays a significantly role in ore or mineral fertilizer production.

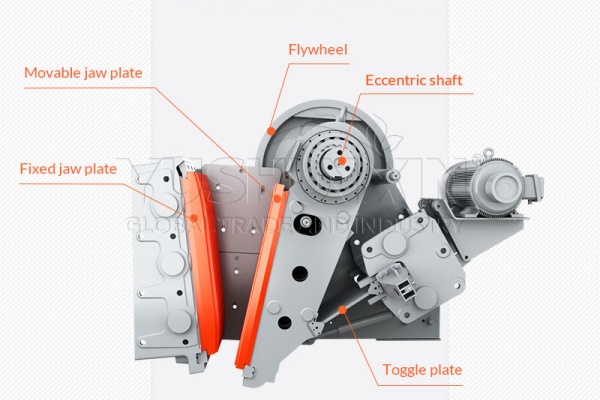

What Is The Structures of Jaw Crusher?

How Does Jaw Crusher Work To Crush Ore For Fertilizer Production?

The jaw crusher operates on a relatively simple principle. The motor drives the eccentric shaft to rotate, causing the movable jaw to make periodical reciprocating movements against the fixed plate. When two jaw plates separating,the rock materials feed into the crushing machine and caught between the fixed and the movable jaws, where the two plates crush down the materials into smaller pieces. Rocks stay in the jaws until they are small enough to meet the requirements. Finally,the mineral powder will through the bottom of the grinder to screen and discharge. The straightforward and effective operation is simple, it still plays an indispensable role in mineral fertilizer production.

What Are Jaw Crusher’s Features?

Parameters of Jaw Crusher

| Model | Max Feed Size (mm) | Discharging Size (mm) | Capacity (t/h) | Motor Power (kw) | Weight (t) |

| SXEP-150*250 | 130 | 10-40 | 1.0-3.0 | 5.5 | 0.7 |

| SXEP-200*300 | 150 | 15-45 | 3.0-6 | 7.5 | 1 |

| SXEP-250*300 | 180 | 15-55 | 5.0-7 | 11 | 2.8 |

| SXEP-250*400 | 210 | 20-60 | 5.0-20 | 15 | 6.5 |

| SXEP-400*600 | 340 | 40-80 | 16-20 | 30 | 7 |

| SXEP-500*750 | 425 | 50-100 | 40-110 | 45 | 9.7 |

| SXEP-600*900 | 500 | 65-160 | 90-180 | 55 | 12 |

| SXEP-800*900 | 600 | 80-140 | 100-220 | 75 | 15.6 |

| SXEP-750*1060 | 630 | 60-150 | 110-320 | 90 | 17 |

| SXEP-900*1060 | 700 | 100-160 | 230-390 | 110 | 31 |

| SXEP-900*1200 | 750 | 110-165 | 220-450 | 132 | 52 |

| SXEP-1000*1200 | 900 | 115-195 | 315-500 | 160 | 55 |

Why Mineral Fertilizer Manufacturers Choose Jaw Crusher?

Manufacturers from ore fertilizer production industry opt for the jaw rock crusher for several compelling reasons:

To begin with, it is an ideal machine for primary crushing stage, it effectively reduces large rock material sizes, making subsequent processing more manageable.

What’s more, it suits for many rock materials. From hard granite to softer limestone, the jaw shredding machine can handle a vast array of materials, making it suitable for diverse process applications.

Besides, the low operational costs as well as coupled with high productivity. In this case, it becomes an economically viable option for manufacturers looking to optimize their processing operations.

Last but not least, the jaw crushers’ ability to process recycled materials not only expands the application range of them, but also aligns with global sustainability efforts, making it an environmentally friendly choice for manufactures.

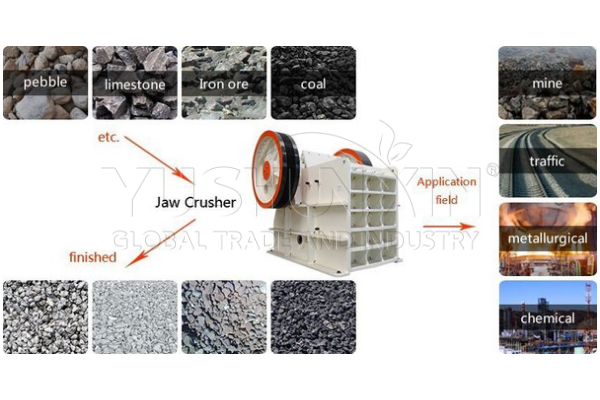

What Materials Does Jaw Crushing Machine Could Process?

Jaw shredding equipment have a broad range of applications and can grind various mineral materials such as:

Limestone, barite, bentonite, kaolin, gypsum, cement, dolomite, marble, calcite, phosphate rock, fluorspar, potash feldspar, talc, lime, quartz, activated clay, activated carbon, etc.

Furthermore, after grinding into fine powders by Jaw crusher, these mineral materials are finally put in use in various industries, especially in rock and ore making fertilizer fields.

In conclusion, Jaw Crusher is an essential and versatile machine in processing rocks and ores in mineral fertilizer production.Its simplicity, durability, and ability to process high-quality materials make it a priority among ore fertilizer manufactures.The Jaw Crusher is an indispensable equipment that can greatly improve the productivity and efficiency of ore fertilizer processing.As advancements in material science and engineering continue to evolve, the Jaw Crusher is poised to remain at the forefront of industrial crushing solutions, driving productivity and sustainability in material processing endeavors.

If you are looking for the most efficient crushing equipment,then a Jaw Crusher is your best choice.