Ore Fertilizer Crusher Machine

Mining, chemical industry, building materials, etc.

1-60 T/H

5.5-180 kw

10+

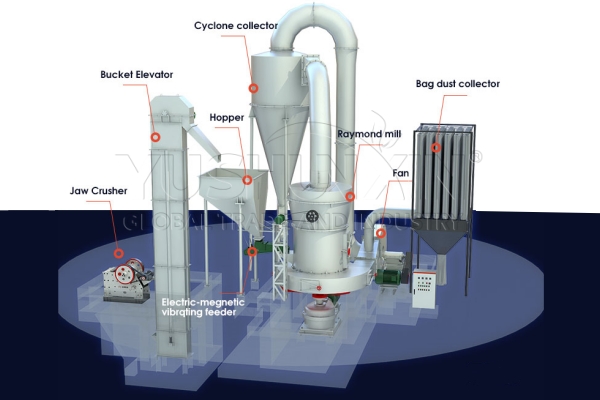

Ore fertilizer crusher machine is a series of professional equipment in the production of mineral fertilizers. And, its function is to crush and pulverize various types of ores into fine powders or smaller pieces. Particularly, this size reduction is essential for improving the homogeneity and reactivity of the materials, which directly impacts the efficiency and effectiveness of the resulting fertilizers. Moreover, these machines can crush and grind various mineral rocks or ore materials, to produce fine powder or smaller pieces that can serve as a base for creating different types of fertilizers. Thus, the process not only involves size reduction but also the homogenization of the materials, ensuring a uniform end product that is essential for the effective application of fertilizers.

What Types Of Ore Fertilizer Crusher Do We Have?

The ore fertilizer crusher machine has a wide range of applications and plays a crucial role in fertilizer production. Specific shredders are required to crush various materials for the production of different types of fertilizers, including ore fertilizer crusher, organic fertilizer crusher, and compound fertilizer crusher. Moreover, the suitability of these fertilizer shredders varies depending on the characteristics and composition of the raw materials used.

Ore Crusher for Sale

Organic Fertilizer Crusher

Compound Fertilizer Crusher

How Does Ore Fertilizer Crusher Work?

How To Select The Right ore fertilizer crusher For Your Project?

Selecting the most suitable ore fertilizer crusher for your project is crucial for achieving maximum efficiency and cost-effectiveness in mineral fertilizer processing. The choice of crusher depends on several factors related to the material being processed and the production requirements. When you select a appropriate ore fertilizer crusher among many types of crushers, factors such as material characteristics, desired output size, capacity requirements, cost, and quality should be taken into consideration. Accordingly, choosing the right crusher is a process that you should have detailed awareness of your specific requirements. In addition, if you still confuse about how to choose a crusher, you can also contact our manufacturers who can help to customize the machine specifications as you want. More importantly, the optimal choice can not only reduce necessary operating costs but also enhance productivity.

In essence, ore fertilizer crusher machine is foundational to the fertilizer manufacturing process. Their ability to efficiently and effectively reduce the size of ore or rock materials directly impacts the quality and effectiveness of the final ore fertilizer. Equipped with high-quality, durable, and efficient crushing equipment is not only beneficial for manufacturers in terms of operational savings but also contributes positively to sustainable agricultural development.