n July 25, 2024, a mining company from Gladstone, Australia, reached out to Yushunxin with an intriguing inquiry. The company, specializing in alumina powder processing, sought a reliable granulator for transforming powdered material into granules. This request highlighted the company’s need to enhance its production capabilities and ensure a consistent product output. The mining company was particularly interested in a solution that could handle their specific requirements, including processing alumina powder with a feed mass rate of 0.84 tonnes per hour.

Fertilizer Granulation Plan In 5T/H American Mine Plant

Australian Mineral Fertilizer Granulation Requirements

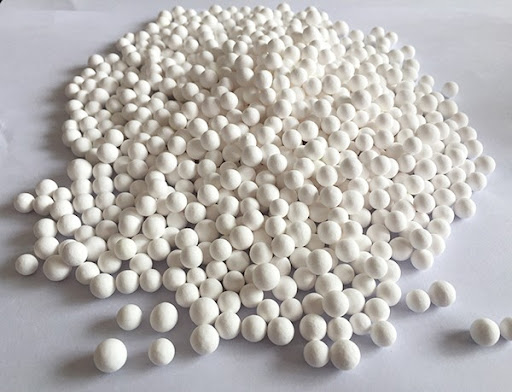

The customer outlined specific parameters, starting with a required feed mass rate of 0.84 tonnes per hour and a volumetric flow rate of 3.51 cubic meters per hour. The bulk density of the alumina powder stood at 240 kg/m³, with the powder being completely dry and operating at a temperature of 80°C. Given the delicate and precise nature of alumina powder, maintaining particle integrity throughout the process was a top priority. The client initially considered the new-type organic fertilizer granulator, anticipating it might handle the dry powder adequately. However, due to the nature of the alumina, which lacks the moisture content typically needed for wet granulation methods, Yushunxin advised against this choice, ensuring the customer fully understood why dry granulation would be the most effective solution.

<$10,000 Mine Fertilizer Machines

Double Roller Pelletizer

Granular Rotary Screening Machine

The Transportation Plan to Australia

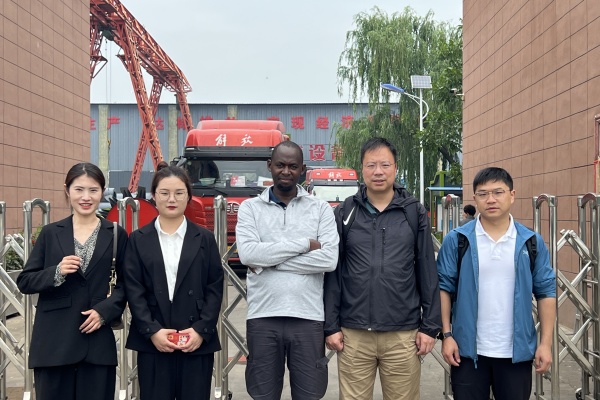

In fact, we provided the Gladstone customer with dedicated support and advice, tailoring each recommendation to their exact needs. To show appreciation for their inquiry, Yushunxin extended a 10% discount on the total equipment price. The transaction price for the granulator and complementary equipment was estimated at approximately $12,000 USD, inclusive of the discount. This pricing covered not only the granulator but also the chain crusher, powder screening machine, and packing scale, ensuring a comprehensive solution that would serve the customer’s production goals.

For delivery, Yushunxin proposed a detailed shipping plan. The equipment would first be transported to the Chinese port of Tianjin, where it would then be shipped to Gladstone Port in Australia. Given the size and complexity of the machinery, it was decided to ship the equipment in two 40-foot containers. The estimated shipping cost for this route is around $4,000 USD, and the estimated transit time is 25 to 30 days. Once the equipment arrives in Gladstone, Yushunxin’s team will assist with the installation at the customer’s mining facility, ensuring that the machines are properly configured for optimal performance. Installation is expected to take place in early September 2024, following delivery in late August. The customer can then begin full-scale production by mid-September, with Yushunxin providing ongoing support throughout the operation process.